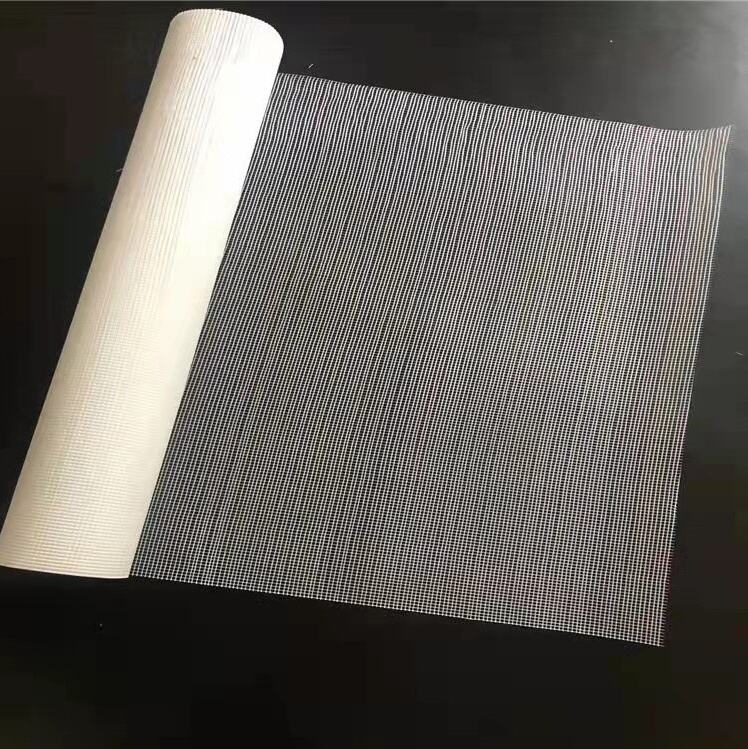

Robur Fiberglass in Usu Aviatorio

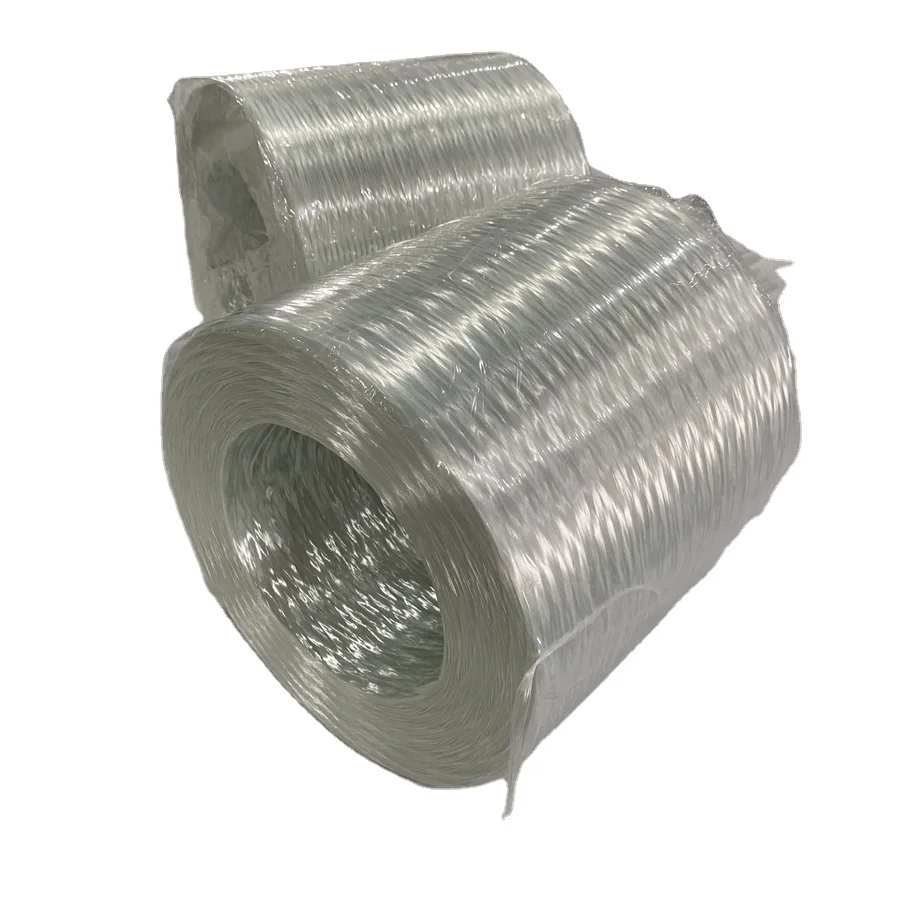

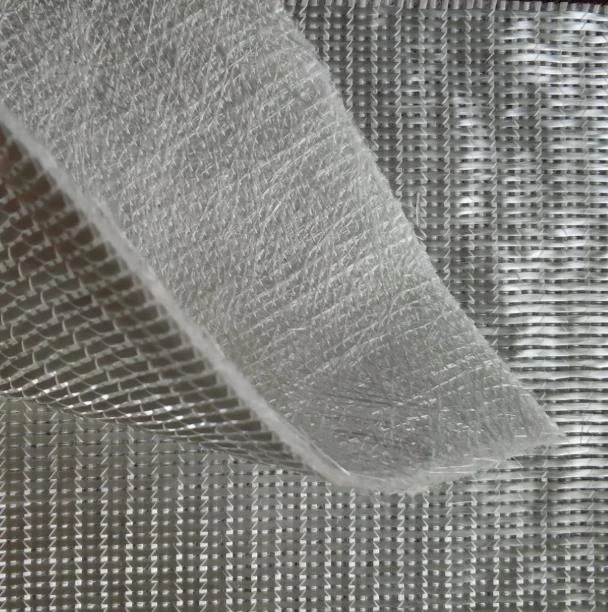

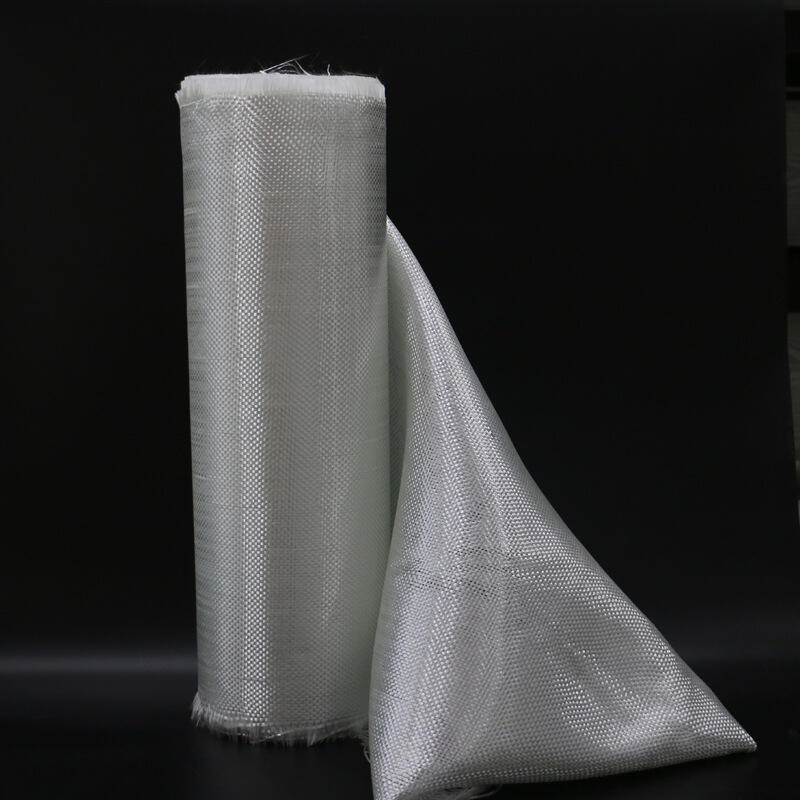

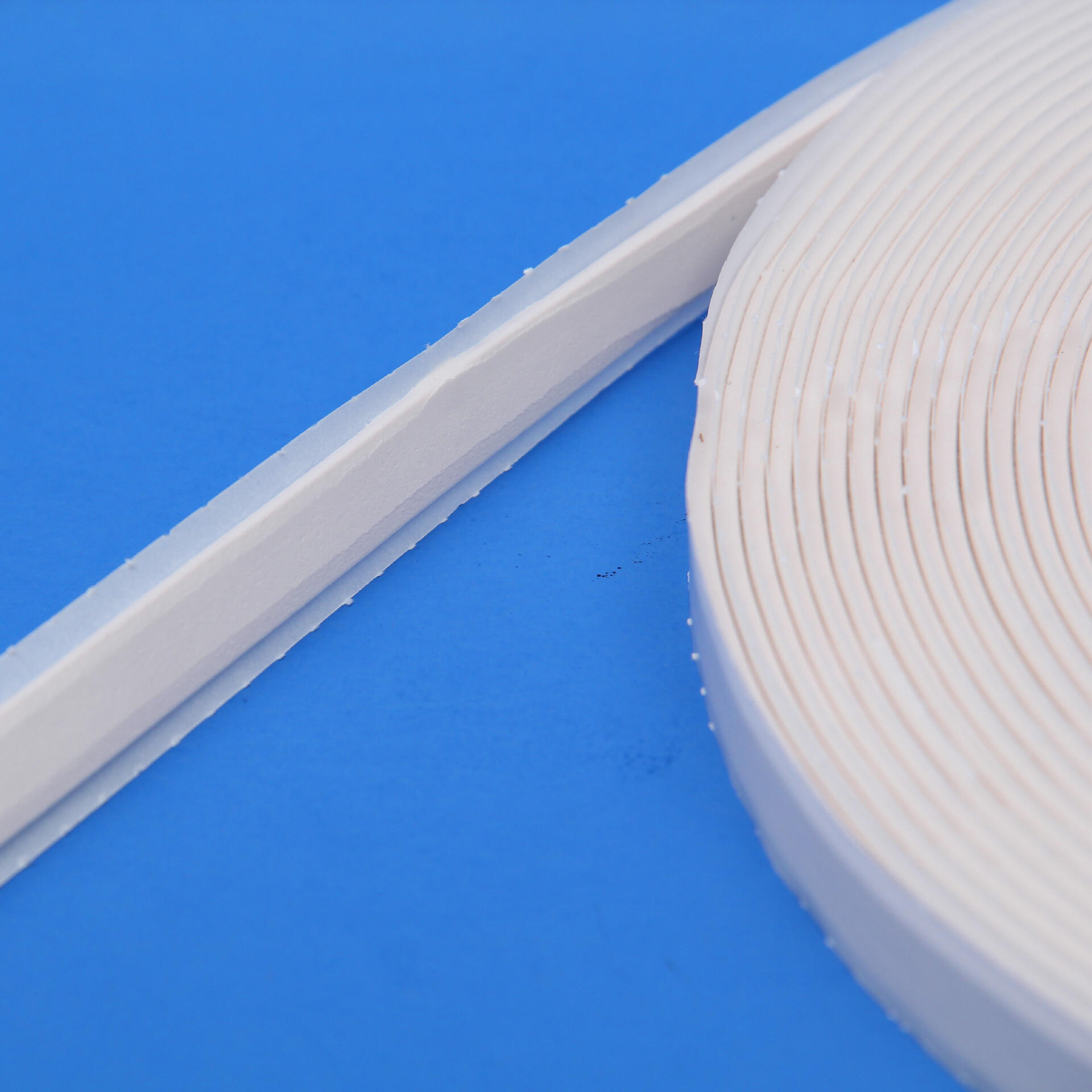

Fibra glassis est valde levis, sed etiam vere exemplum. Id significat quod fibra glassis debet posse tolerantiam magnam varietatem conditionum. Itaque, res sicut fibra glassis resistit frigus extremum et calorem, altam pressionem (cogita volatum in altitudine alta), etc. Et, tempestas mala (e.g., imber/nix). Praeterea, metallum humidum habet problematum ferrugine quod fibra glassis optat ut habeat. Haec sunt mirabilia qualitates fibrae glassis, quae est materia bona pro partibus in aere plano quae debent esse fortes et fideles in altitudinibus altis.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ