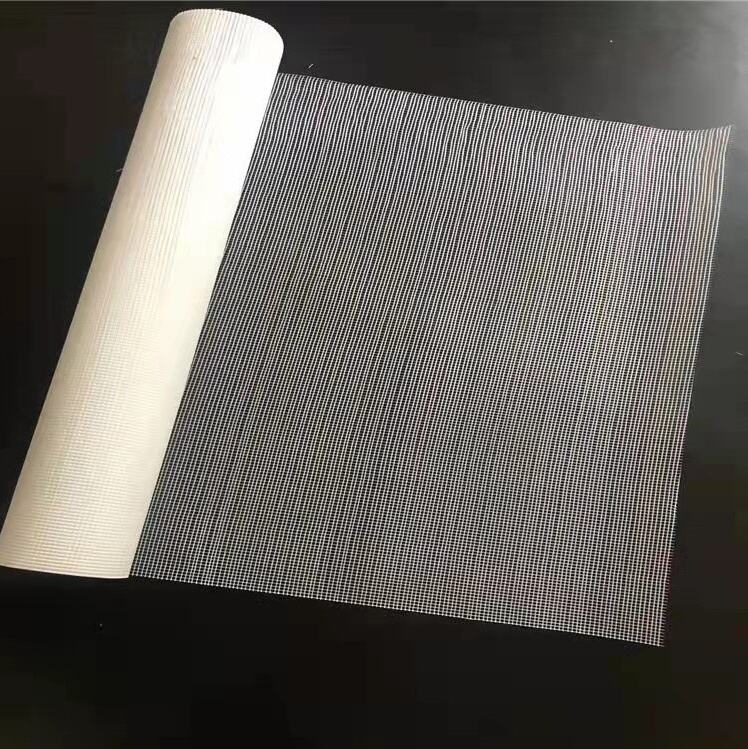

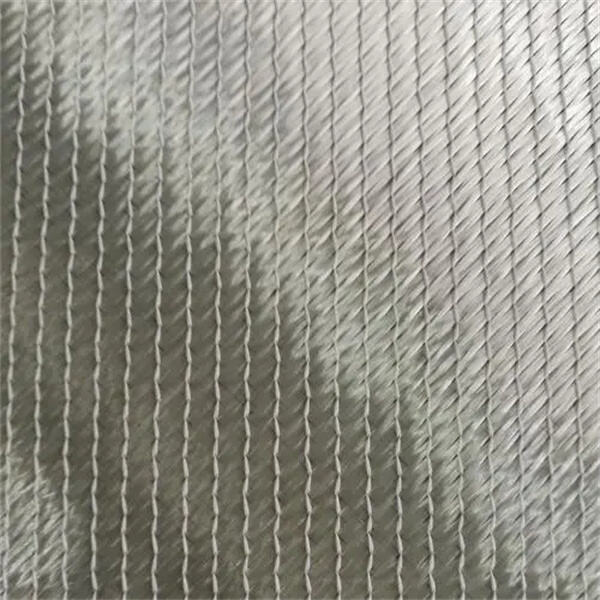

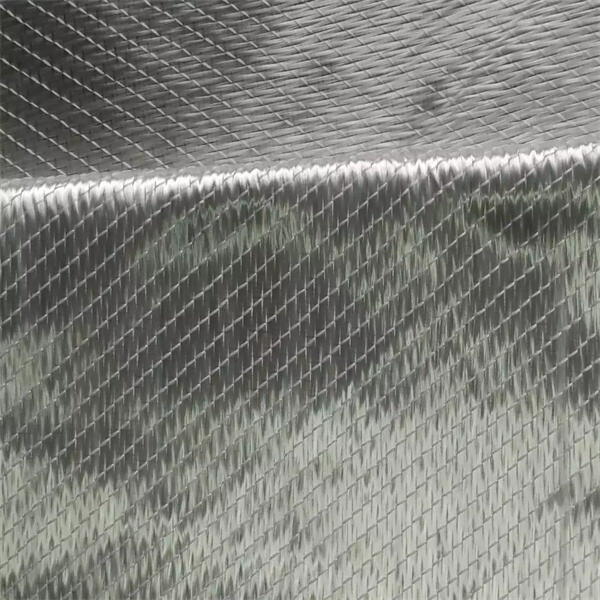

If you have traveled with an airplane at some point in your life, then you must have observed the significance of all things to be sound and secure. Airplanes soar high in the sky, and safety comes first for all involved. That’s also why aerospace engineers, the people who design airplanes, are always on the lookout for new materials and technologies that might make flying safer. They have found one material that is very useful and that is fiberglass. AMP is working its ass off to build new and exciting fiberglass products for the plane industry.

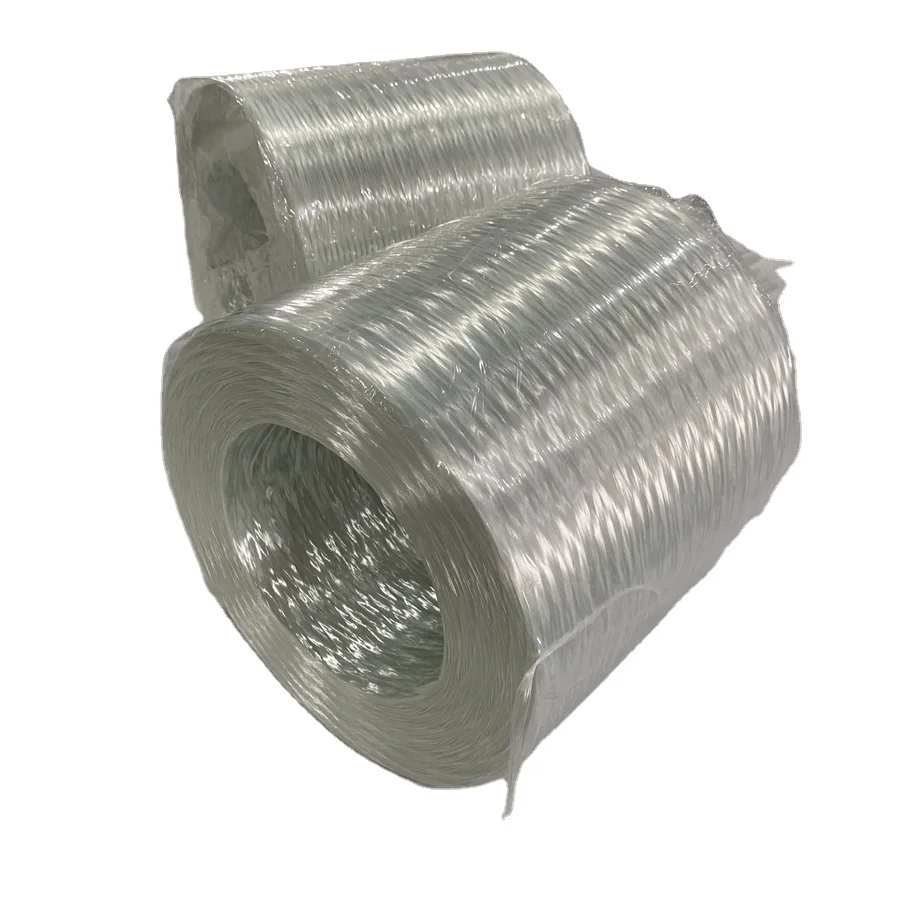

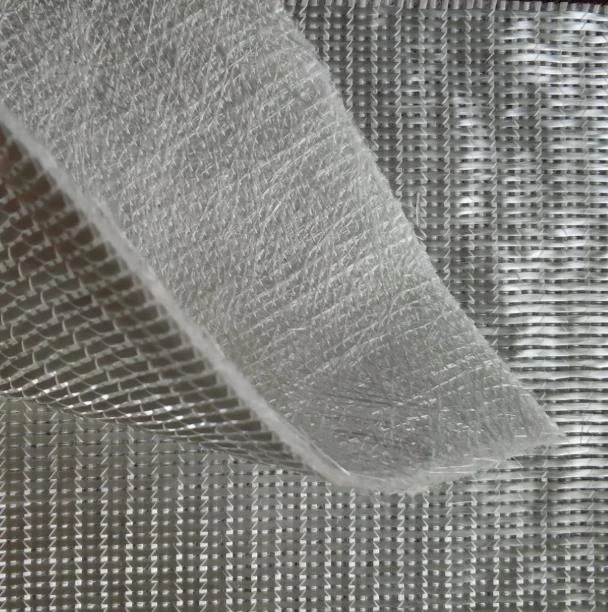

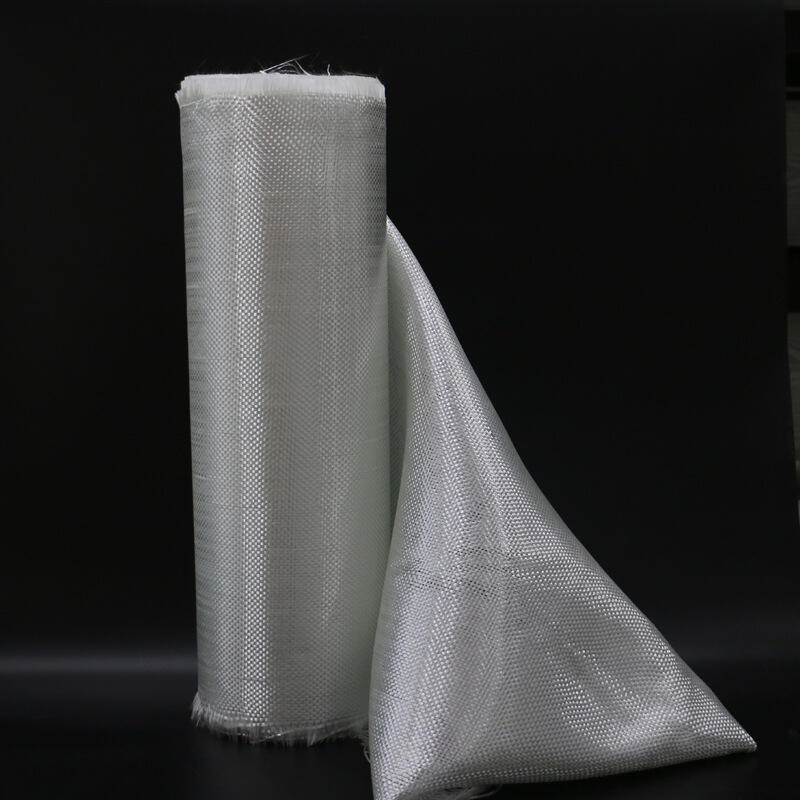

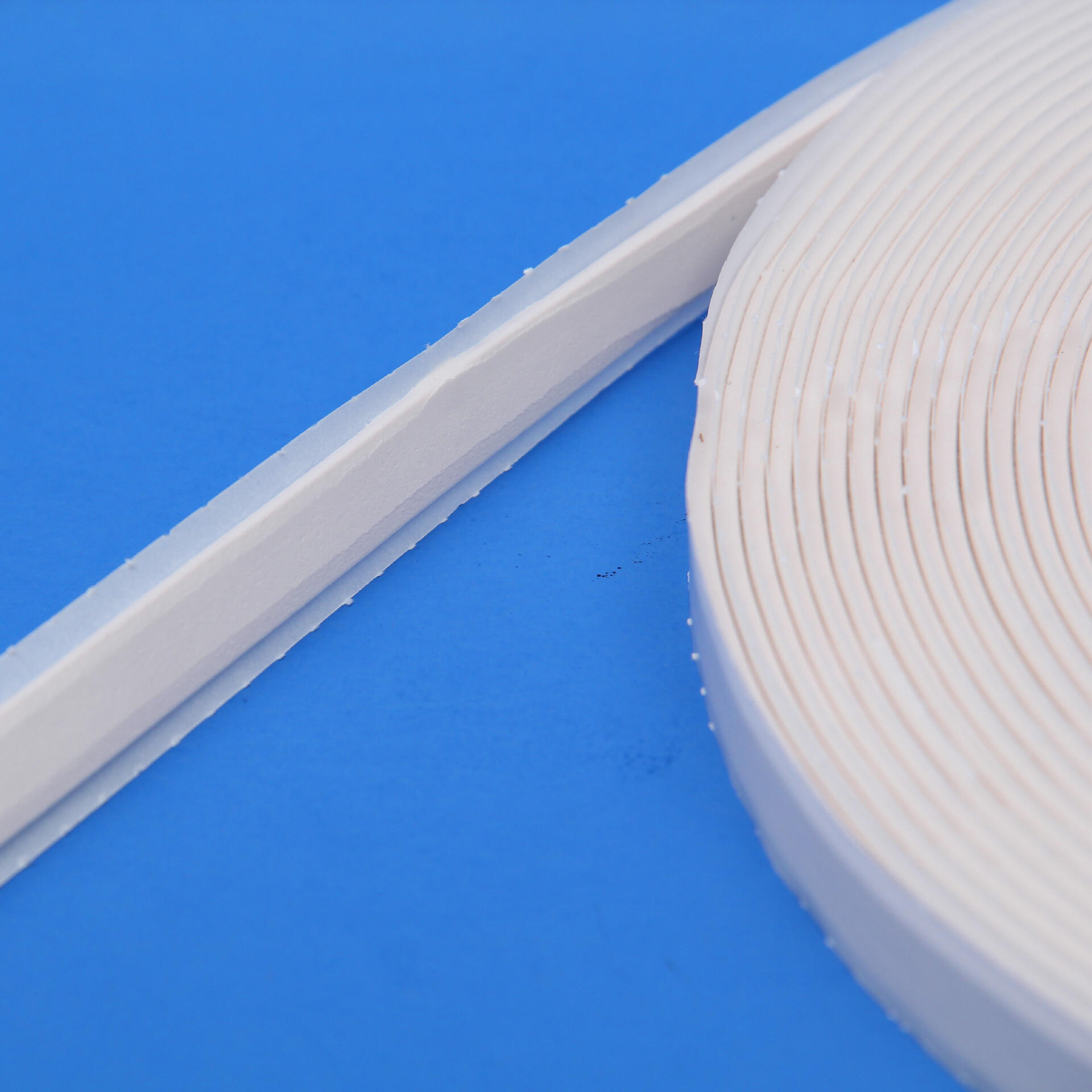

Safety must always be the primary consideration when designing and building airplanes. And this is where fiberglass enters center stage in aerospace engineering. Fiberglass: A super lightweight yet very strong material. That is, this can be molded in a variety of parts that planes require. It is ideal for producing large components of aircraft such as wings, bodies and other significant parts. Airplane makers can make planes that are stronger and safer by using fiberglass. Knowing this, you will understand that these airplanes can deal more effectively with the stresses and challenges of flying and thus ensure that everyone on board — both airline passengers and crew members — have a safe flight.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ