Steel has been a material of choice for a very long time when we speak of materials for anything construction related. Steel has been used to create sturdy structures such as bridges and skyscrapers. Steel, though, does have some downsides. For one thing, it can be quite heavy, making it difficult to maneuver and use. One more thing — steel can rust, especially when exposed to water, salt, or some chemicals, and over time, steel can dissolve, robbing the part of proper function. That will cause the steel to rust, weakening it over time and making it less safe.

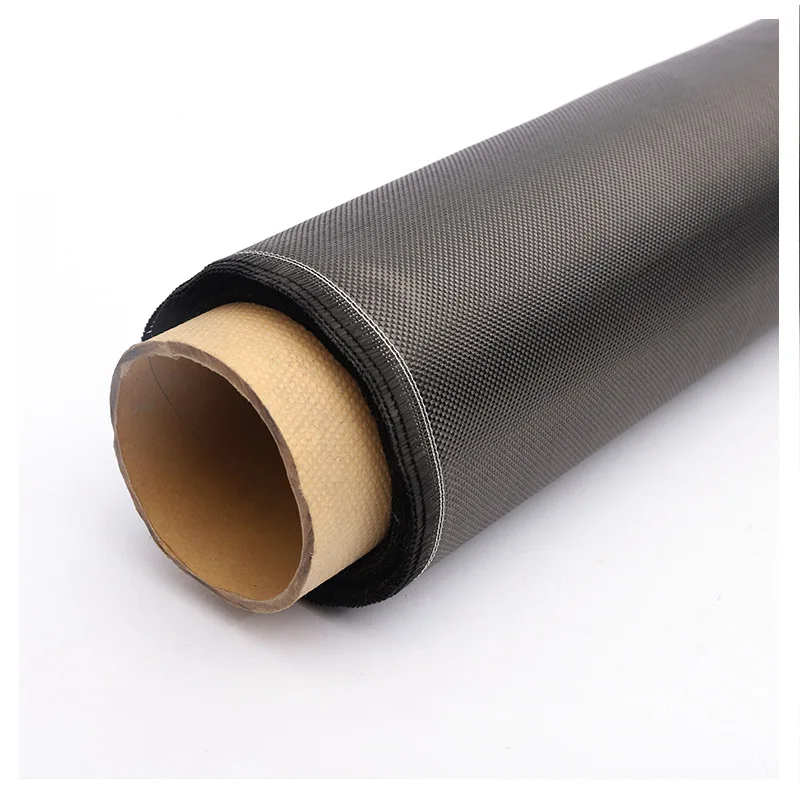

A critical process employed in producing this fiberglass is pultrusion. Fiberglass pulled through a mold in a manufacturing technique called pultrusion process (that's a specialty process that essentially pulls fiberglass through a hot mold to create long, uniform, strong parts). This process enables AMP to produce a wide range of different fiberglass profiles with varying forms and structures. They help us build all types of structures, from bridges and buildings to renewable energy plants that produce clean energy.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ