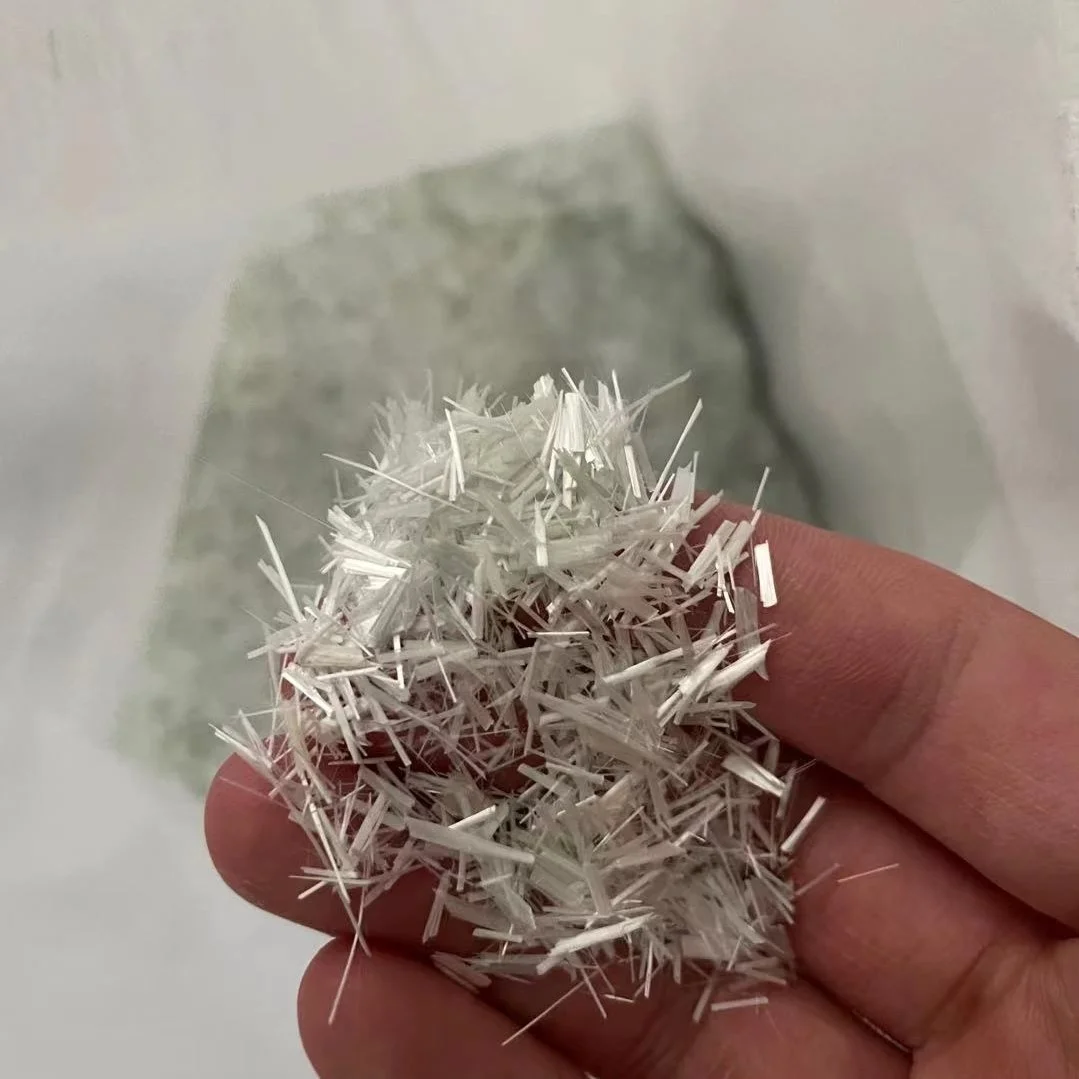

How Chopped Strand Glass Fiber Works

For example, chopped strand fiberglass has a very good strength-to-weight ratio. That means it is extremely strong and can support a very heavy weight but is also very light. This unique attribute of strength and lightness is an excellent choice when producing goods that require structural integrity while remaining portable, such as an automobile part or marine vessel.

Wind Turbines Wind turbines are tall structures which assist in producing energy from the wind. To create these turbines, the blade material was sourced from chopped strand glass fiber and cross-matched to make them strong enough to withstand harsh weather conditions for many years.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ