Utilizing Chopped Strand Fiberglass

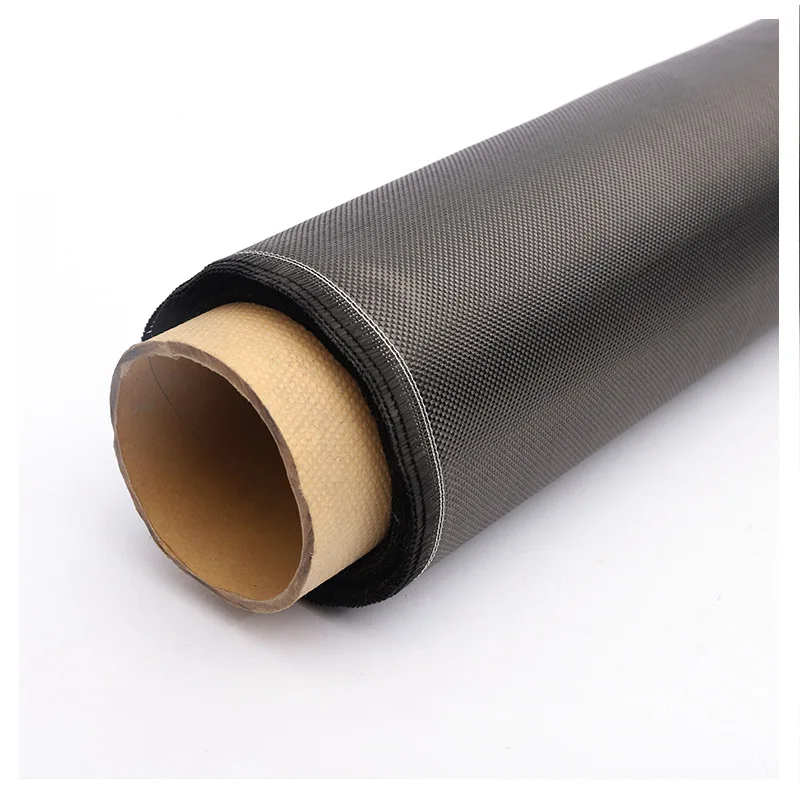

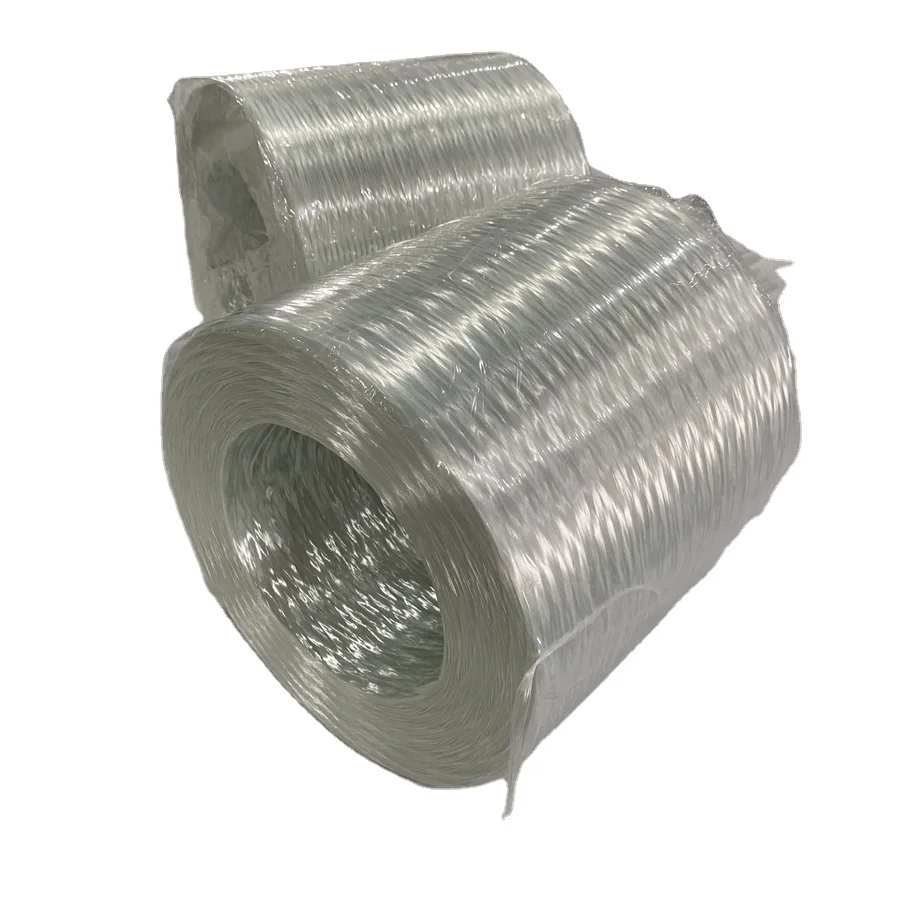

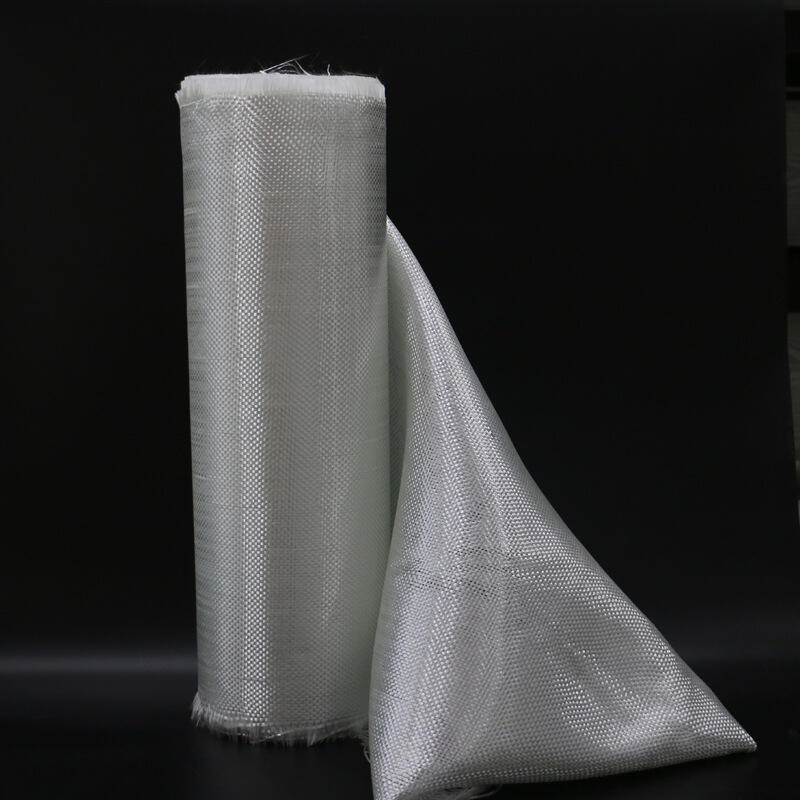

Chopped strand fiberglass can be utilized within a variety this can be wide of, from watercraft building to manufacturing and automotive. The AMP expandable braided sleeving must initially be blended with a resin binder to develop a composite product to use sliced fiberglass this might be strand. The materials could be molded, then shaped, and processed to develop the product this might be specified.

Service and Top-notch Chopped Strand Fiberglass

Whenever dealing with chopped fiberglass strand it is necessary to purchase a supplier who can supply top-quality services and products and solution and excellent. A supplier and reputable have deep knowledge of the properties and traits of AMP woven roving fiberglass, knowledge working together with the materials inside a genuine range application.

Application of Chopped Strand Fiberglass

Chopped strand fiberglass includes a range and wide of in a real number of industries. Some of the most typical applications consist of vessel building, automotive production, wind generator blade production, and building products such as fiberglass insulation and rebar. Simply by using AMP aramid honeycomb core your products or structures, you can enhance their power, durability, flexibility, and resistance to weathering and corrosion.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ