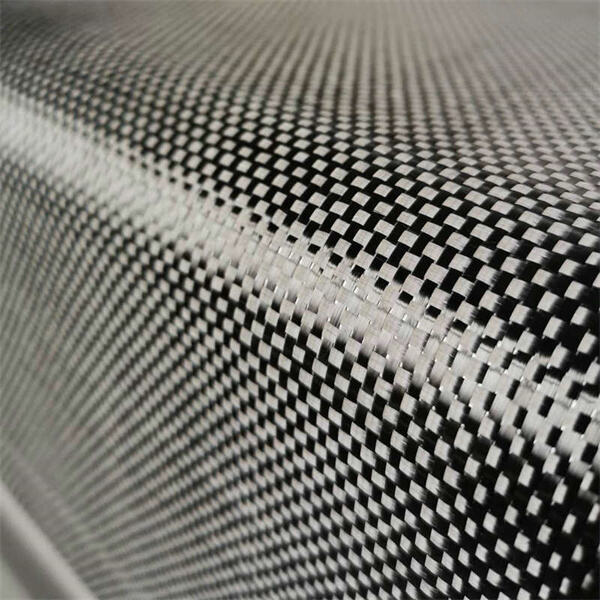

The Interesting Manufacturing Details Of Plain Weave Carbon Fiber

Carbon fiber was a revolutionary new material thanks to its complex and exotic manufacturing process. Raw materials such as acrylic fibers are transformed into pure carbon fiber through a process called pyrolysis. These fibers are woven together in specific ways to form fabrics with a wide range of patterns and styles. But the highest quality weaving that plain weave is known for can be seen with one of these.

Safety Needs to be a Priority with Plain Weave Carbon Fiber

When dealing with plain weave carbon fiber, nothing is more important than safety. When cutting and sanding the material always wear proper safety gloves along with a mask to avoid any harm. Also, a space to work with good ventilation is key for safety (carbon fiber dust over time can be very harmful to breathe). Because of the incredible conductivity of carbon fiber, care must be taken during use not to touch any electrical components.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ