- Home

- About Us

-

Products

- Fiber Glass For Flament Winding Pipe/Tank

- Fiber Glass Pultrusion Materials Pultrusion Profiles

- Fiber Glass Vacuum Infusion Materials/Tool

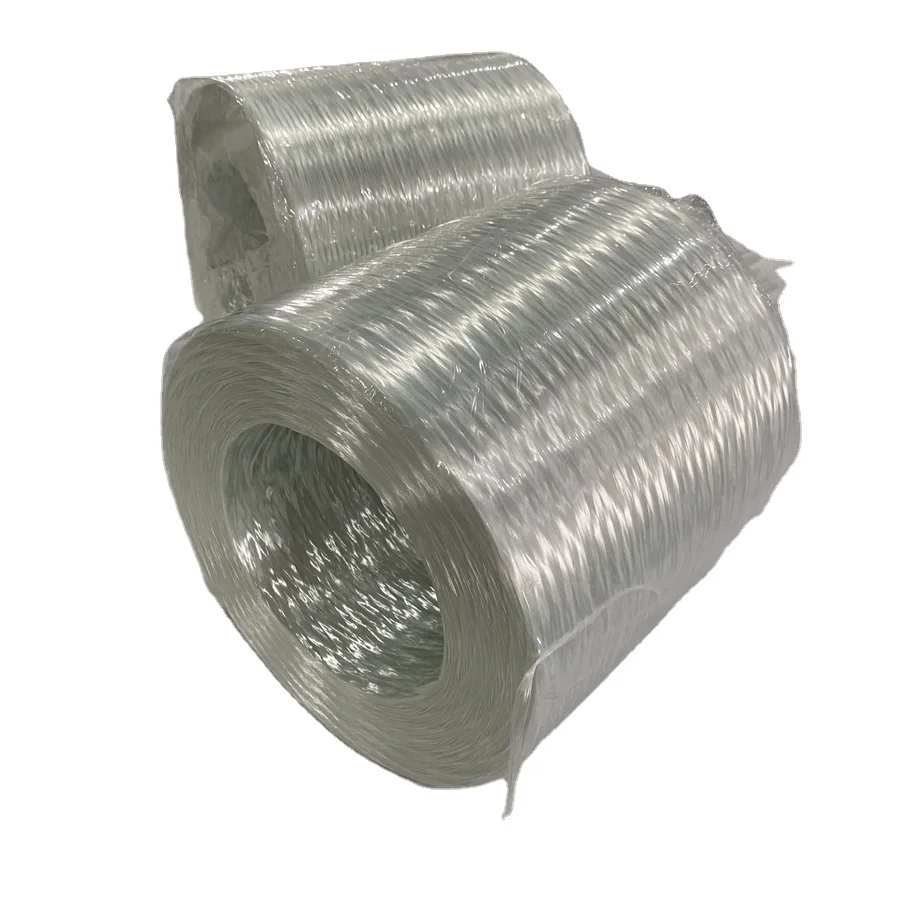

- Assemble/Single Roving

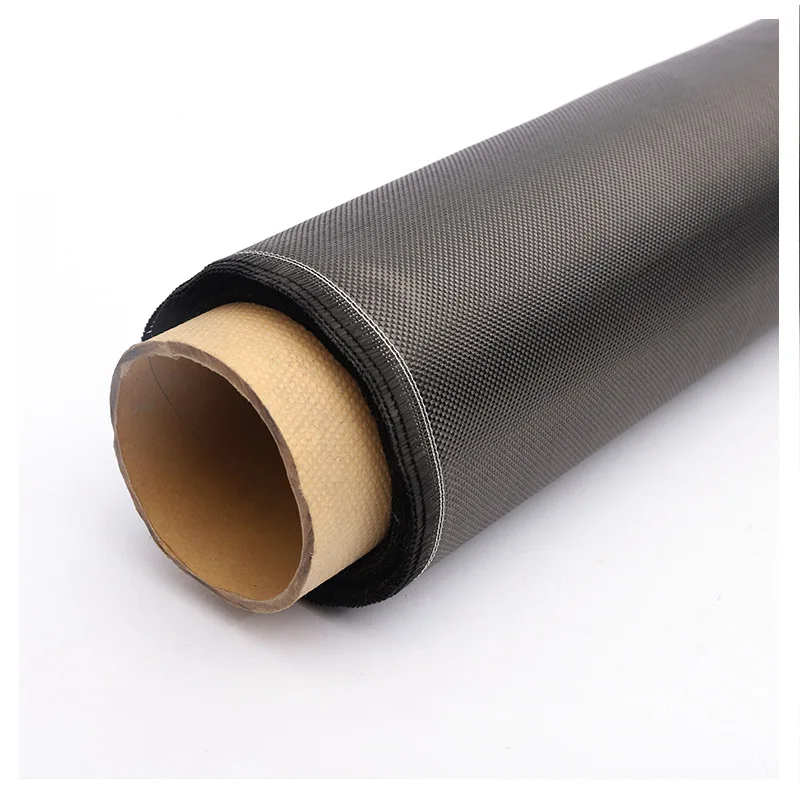

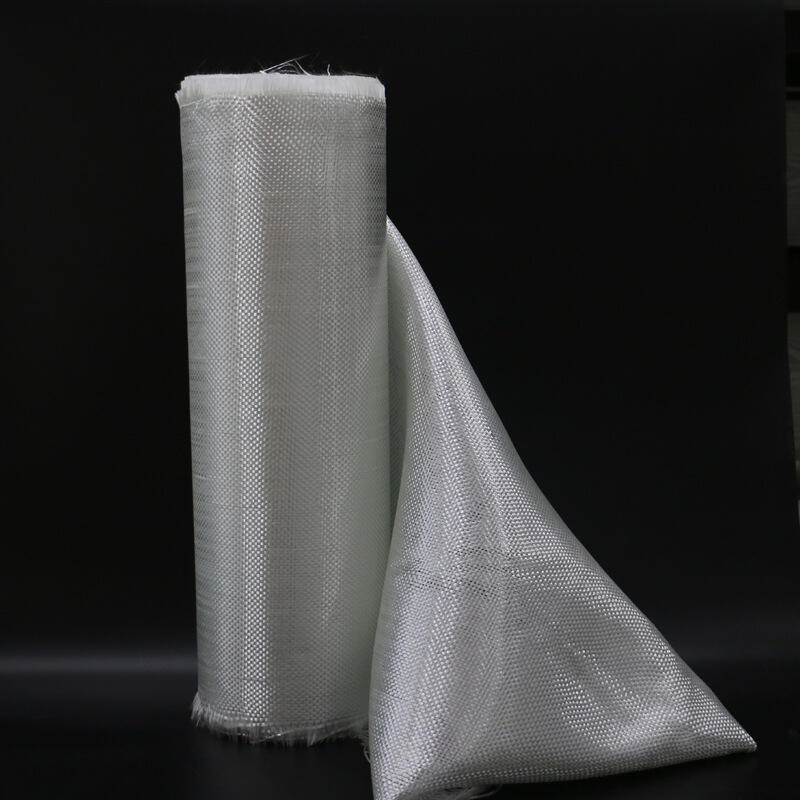

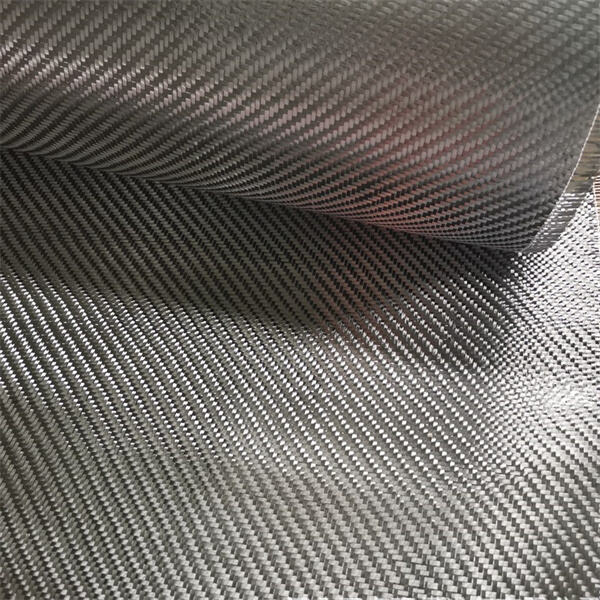

- Fiberglass Fabric

- Chopped Strand Mat

- Chopped Strands

- Unidirectional/Biaxial/Multiaxial Knitting Fabric

- Other FiberGlass Fabric

- Other Chemicals

- Service

- News

- Blog

- Video

- Contact

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ