Fiberglass is an incredibly durable and increasingly popular material for boat building. One such company is AMP, which makes an extremely strong fiberglass for boats and all types of marine craft. In this dialog we will explore the many advantages of fiberglass, how it protects a boat in storm conditions, where fiberglass is found on a boat, innovations and advances in fiberglass technology and the role that supports the entire boat industry.

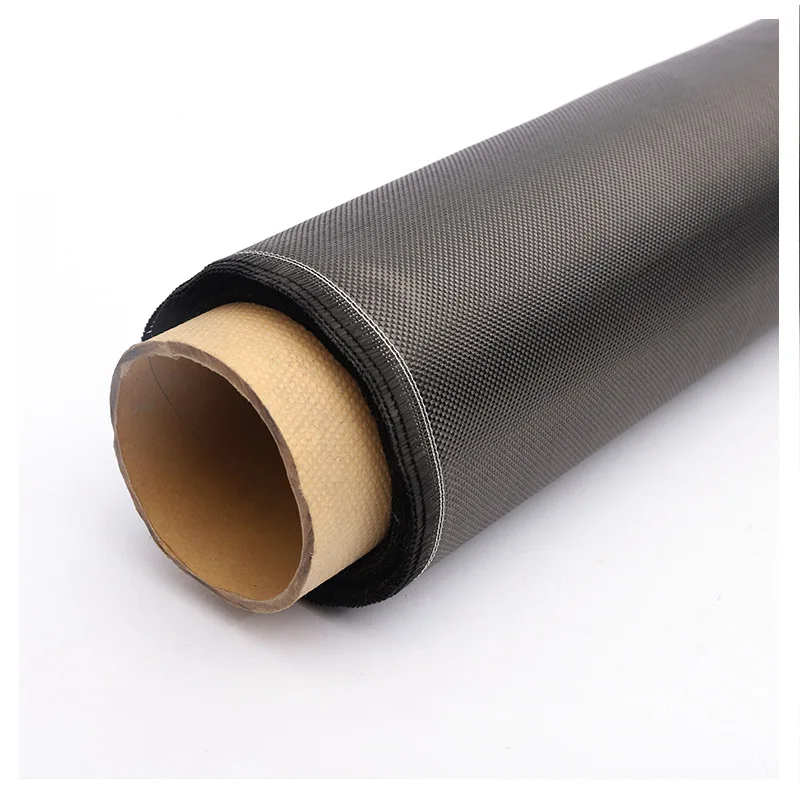

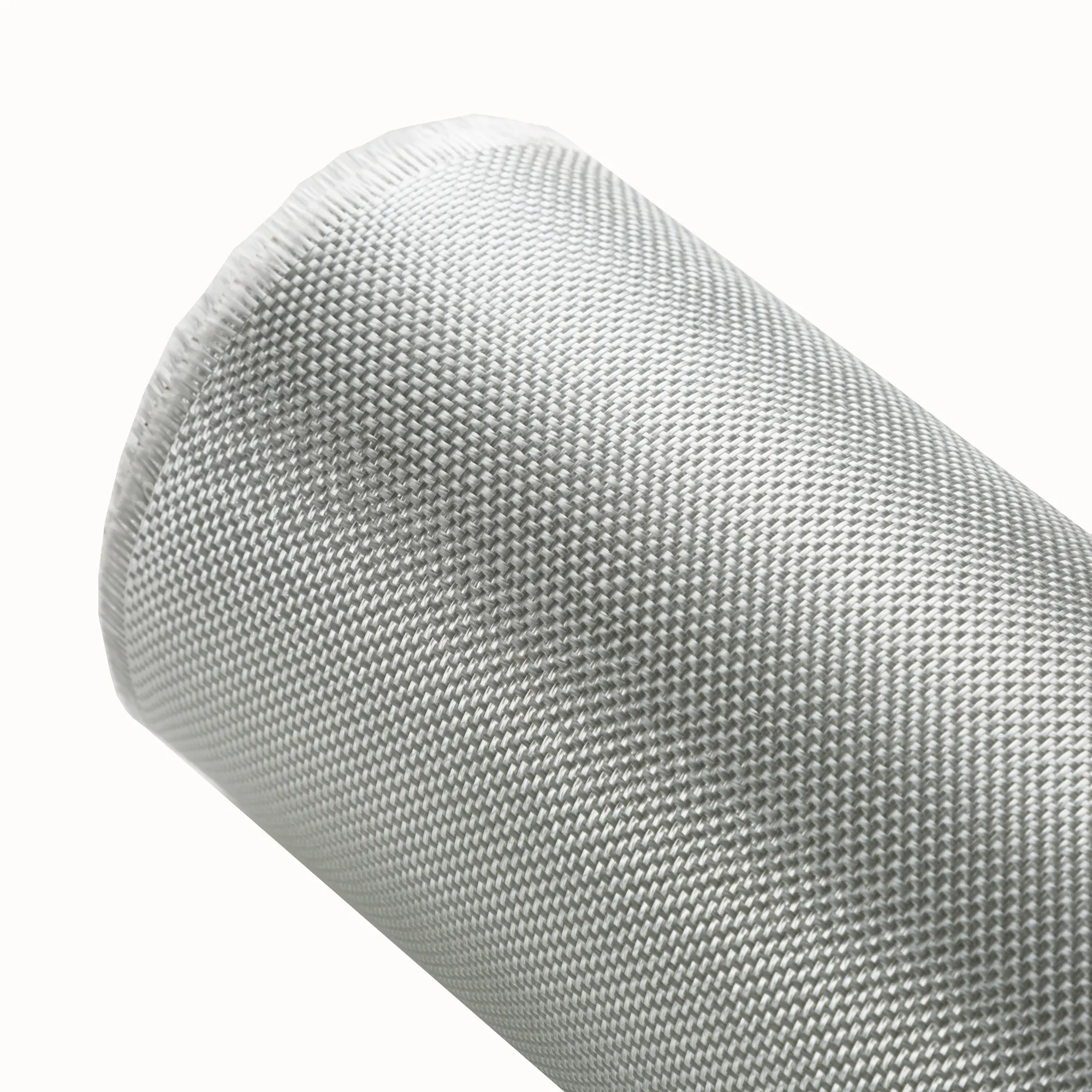

Because it is light, strong and not especially expensive to buy in bulk fiberglass is used for making many boat parts. It is a composite material made from extremely fine glass fibers that are woven together and with the mixture of resin, an adhesive compound. These materials combined yield a durable and elastic material well suited for boat construction.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ