- Overview

- Inquiry

- Related Products

Key Features:

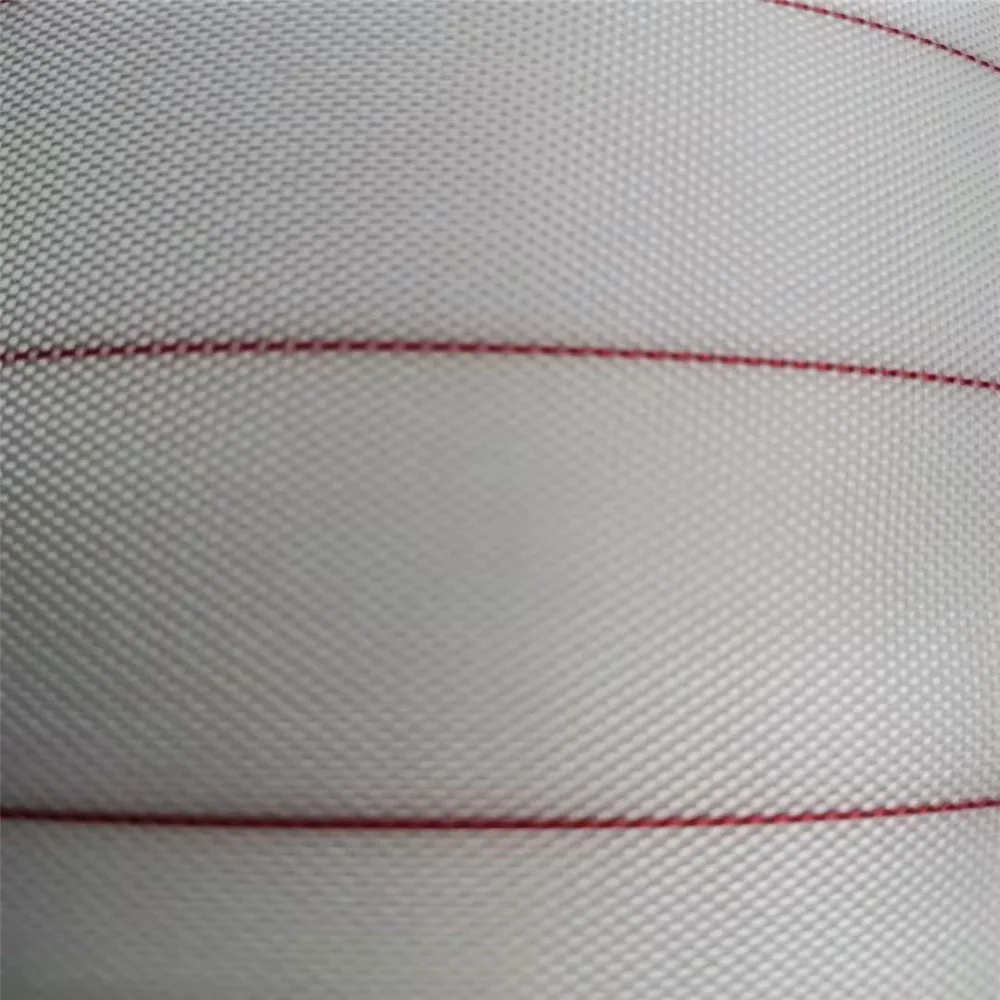

High-Quality Glass Fibers: Made from high-quality glass fiber materials to ensure superior strength and performance.

Optimized Surface Treatment: The rovings are treated to ensure better resin bonding and dispersion, enhancing the overall quality of the composite material.

Good Resin Wet-Out: The fiber structure and surface treatment allow for optimal resin penetration, improving the performance and strength of the final product.

Versatile Compatibility: Suitable for use with various spraying equipment, including manual spray guns and automated spray systems, to meet different production needs.

Improved Production Efficiency: The use of Spray-Up Roving reduces manual labor, increases production efficiency, and lowers manufacturing costs.

Excellent Corrosion Resistance: The composite materials made with Spray-Up Roving are highly resistant to corrosion from various chemicals and harsh environments.

Applications:

Automotive Industry: Used for the production of automotive body panels, chassis, interior parts, and more, providing lightweight and high-strength composite material solutions.

Construction & Decoration: Commonly used in building panels, roofing, bathtubs, swimming pools, and other structural and decorative components.

Marine Industry: Used for manufacturing boat hulls, cabins, and other composite components, offering excellent water resistance and corrosion protection.

Piping & Tanks: Ideal for creating corrosion-resistant pipes, storage tanks, and reactors, providing long-lasting durability.

Sporting Goods: Used in the production of sporting equipment and consumer products, such as skis, windsurfing boards, and more.

Product Advantages:

High Strength & Durability: Spray-Up Roving enhances the mechanical strength and impact resistance of the composite, prolonging the service life of the final product.

Improved Production Efficiency: Suitable for automated spraying equipment, which significantly boosts production speed and consistency.

Cost-Effective: Compared to traditional hand-layup methods, Spray-Up Roving reduces material waste, improves efficiency, and provides a cost-effective solution.

Environmentally Friendly: Free from harmful substances and compliant with international environmental standards.

Packaging & Storage:

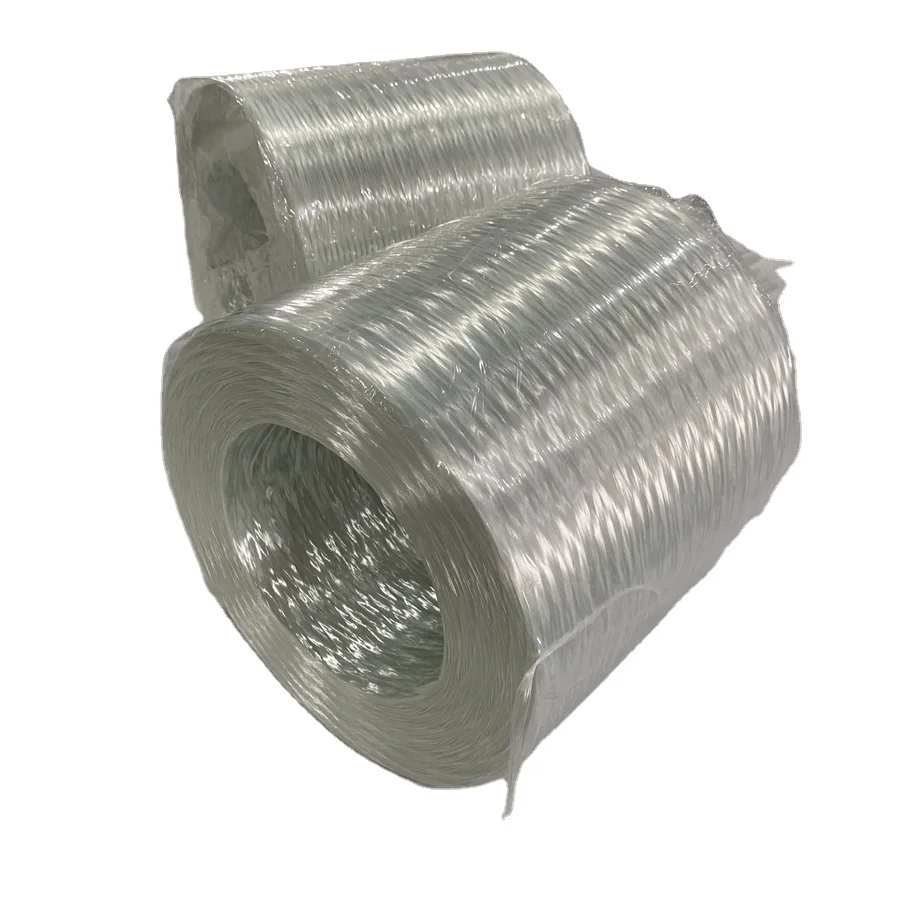

Packaging: Spray-Up Roving is typically supplied in roll form, tightly packed to prevent damage and moisture exposure. Custom packaging options are available according to client needs.

Storage: Store in a dry, ventilated area, away from direct sunlight, to maintain optimal performance.

Spray-Up Roving is a critical raw material in the production of modern composite materials. With its excellent performance and wide range of applications, it has become an indispensable product across many industries. Whether in terms of production efficiency, cost control, or final product quality, Spray-Up Roving offers stable and reliable solutions.

For any technical inquiries or customized product requirements, please contact us. We are happy to provide tailored solutions based on your specific needs.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ