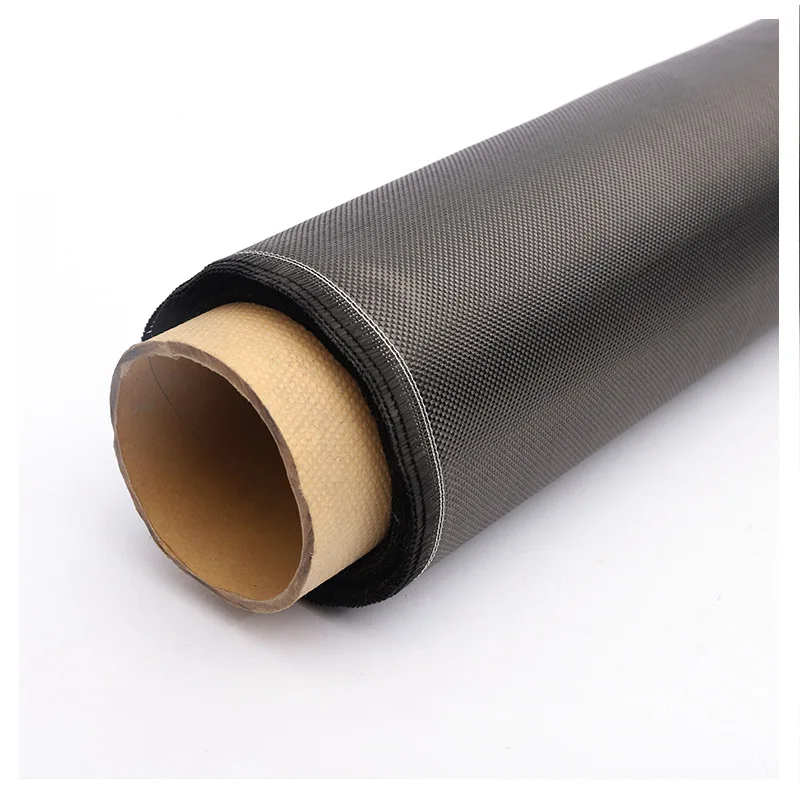

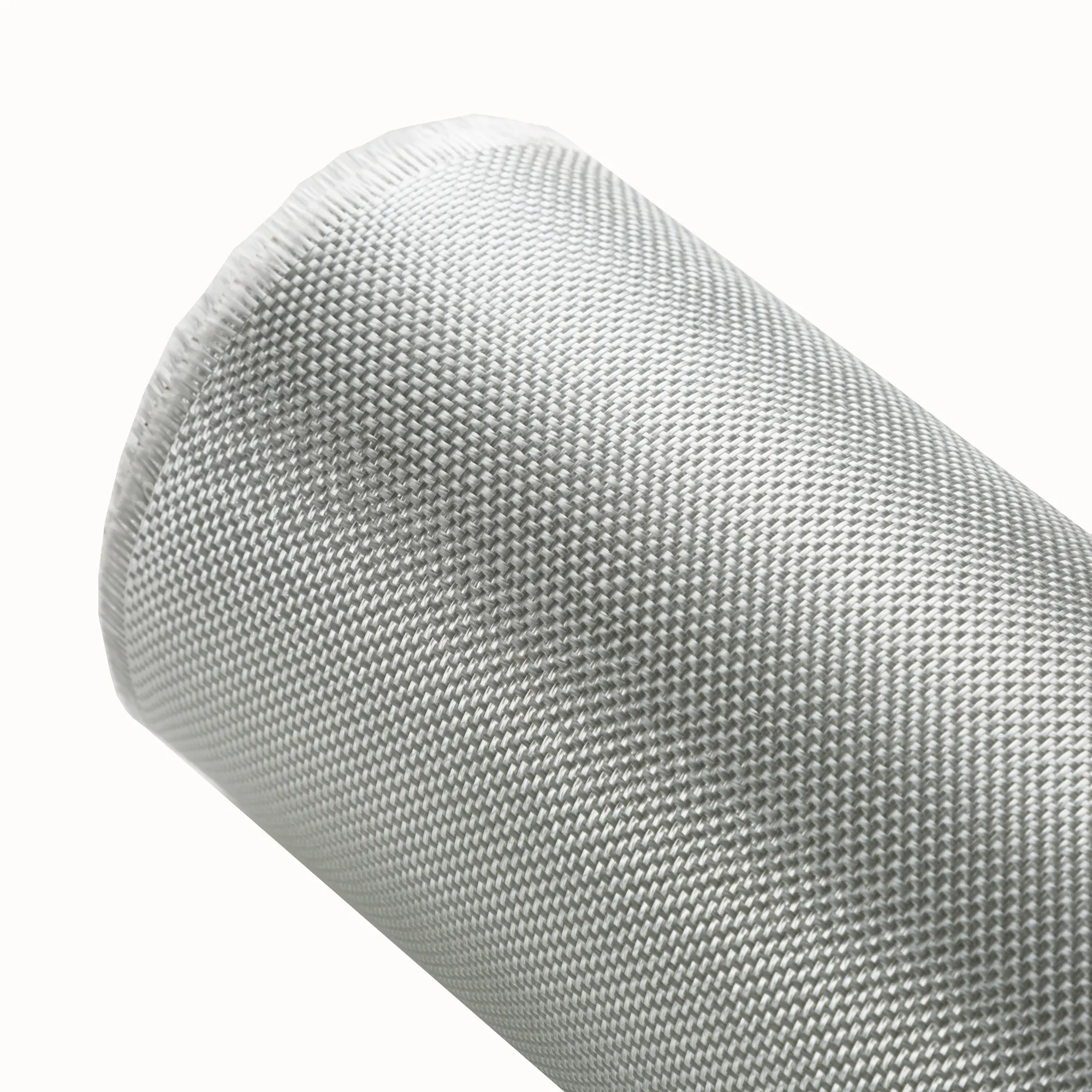

No, you couldn’t have possibly known that cars and other vehicles can be made from materials other than just metal. One of these materials is fiberglass. Fiberglass is a special lightweight-high-strength composite material in terms of car construction. With the multitude of benefits that fiberglass provides, an increasing number of car manufacturers are now utilizing it.

In fact, fiberglass has been around for a very long time — since the early 1900s. But it did not start being used in car making until the 1950s. However, by far the most famous fiberglass-bodied car is the Chevrolet Corvette, introduced in 1953 as one of the first mass-produced vehicles to be made from the material. Many types of fiberglass based cars and vehicles have been invented since then. This covers vehicles of all kinds, racing cars, trucks, and boats too!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ