How to make use?

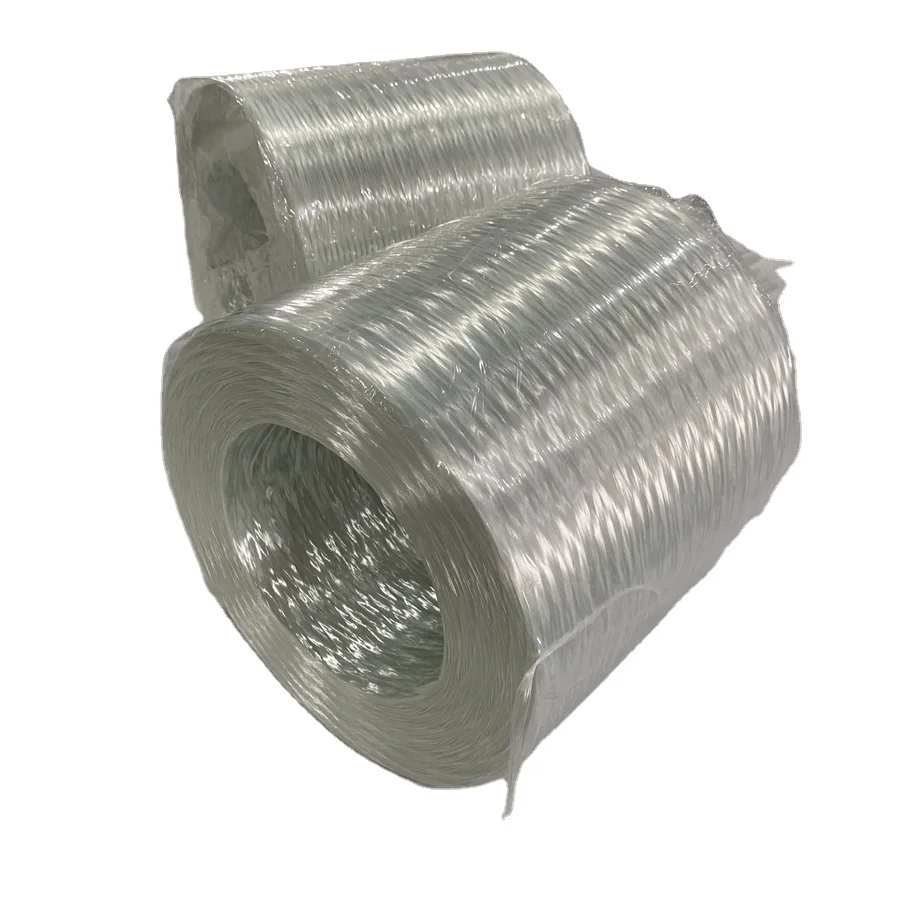

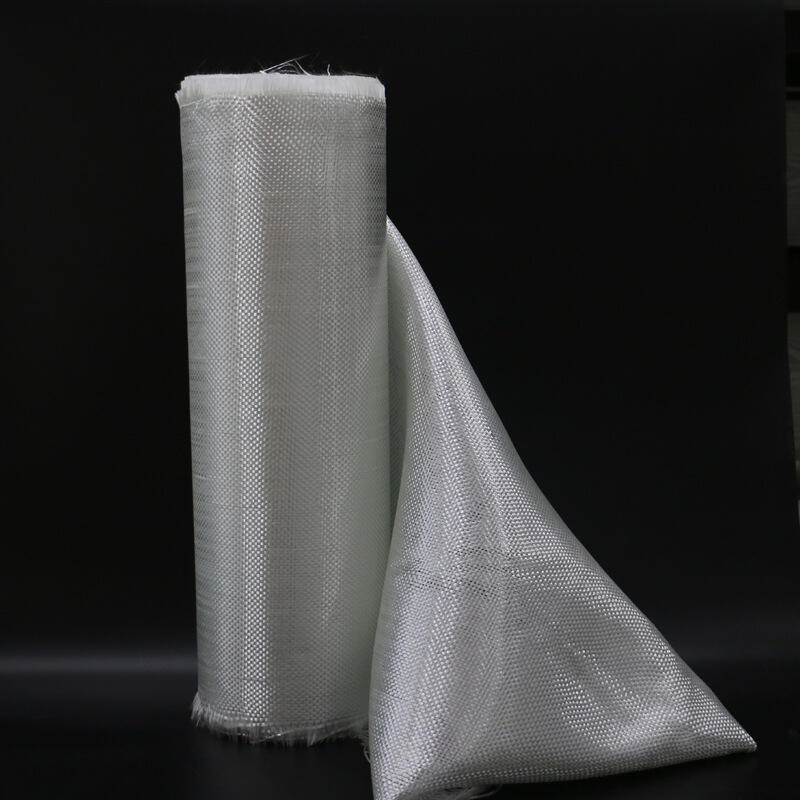

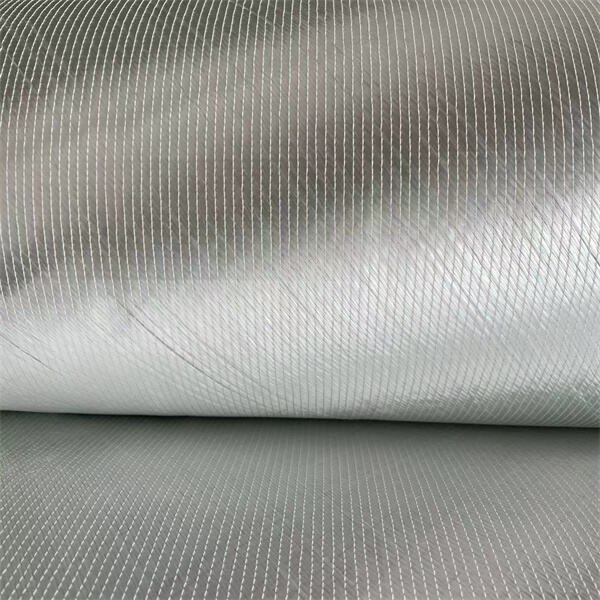

Utilizing fiberglass and biaxial relatively easy, similar to the fiberglass materials created by AMP. Very first, measure and cut the material to the size and it is required. Then, prepare the top to be fused by roughening and cleansing it. Apply a level of epoxy resin to the area and put the biaxial fiberglass into it. Wait for epoxy to cure before adding a topcoat of resin. Sand the outer lining to acquire a finish and it is smooth. Always wear equipment and it is safety as gloves, goggles, and a mask when using the services of biaxial fiberglass.

Service and high quality

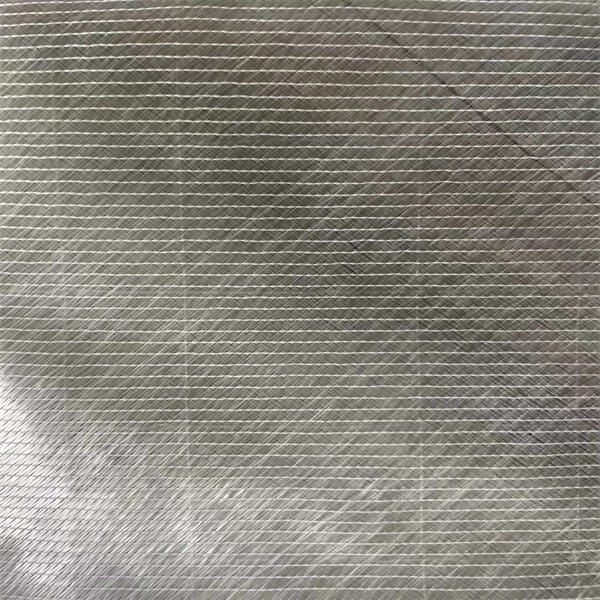

The grade of biaxial fiberglass is of utmost importance, also the AMP's product such as JUSHI fiberglass. It is essential to select a provider whom provides products that are top-quality meet business requirements. A reliable provider will be able to provide technical support, delivery services, and prices and competitive. The supplier also needs to possess a return and sturdy and guarantee for their items.

Application

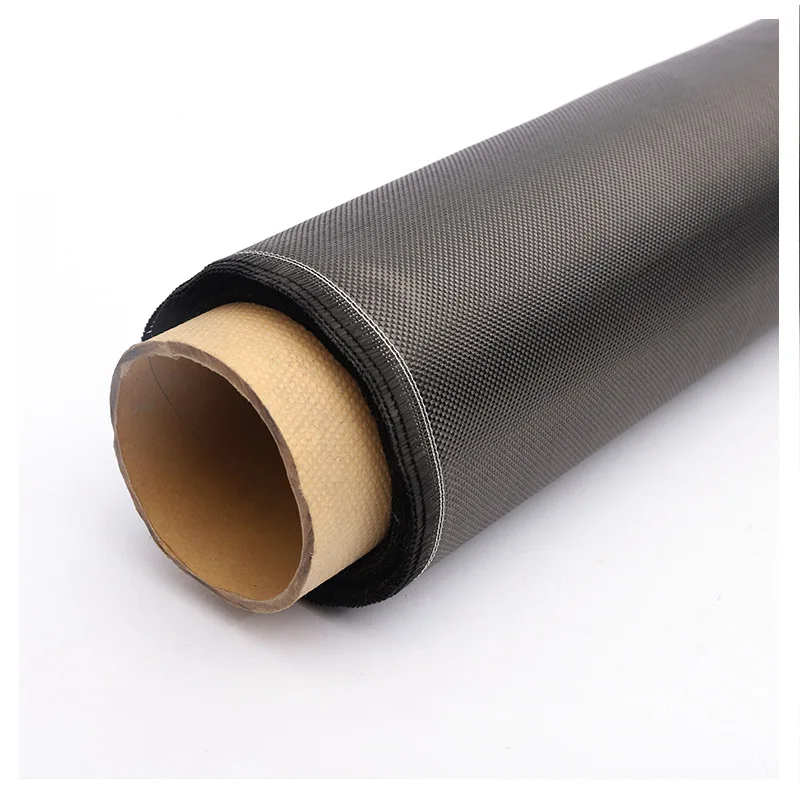

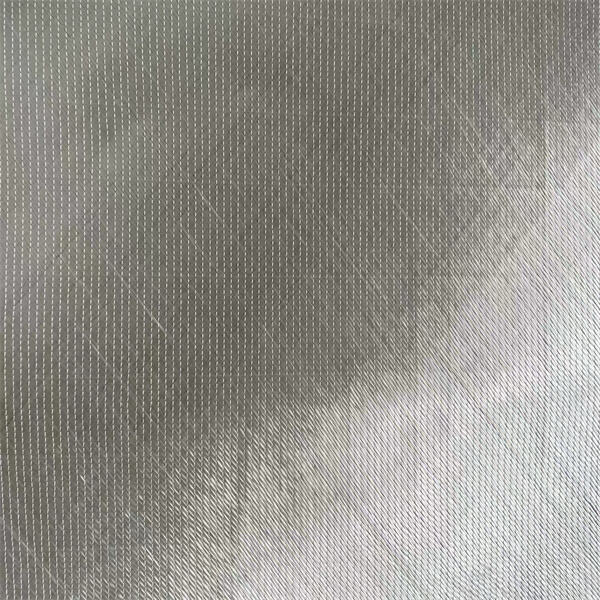

Biaxial fiberglass has application and unlimited, same with the chopped mat fiberglass manufactured by AMP. It can be used in construction, marine, automotive, and companies that are wearing. Some of the specific programs:

1. Building construction - Support of concrete structures, roofing, and cladding.

2. Sports gear - Kayaks, ships, paddle boards, and sports floor coverings.

3. Automotive - Vehicle bodywork, panels, and dashboard.

4. Marine - Hulls, porches, and superstructures of boats and vessels.

5. Electric - Insulation of electric cables, transformers, and insulator rods.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ