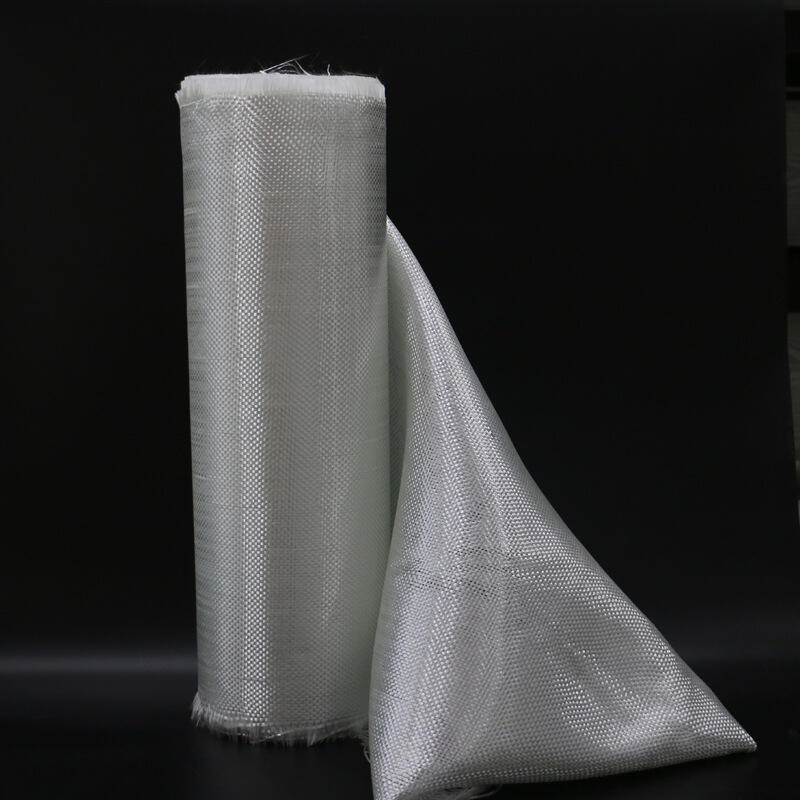

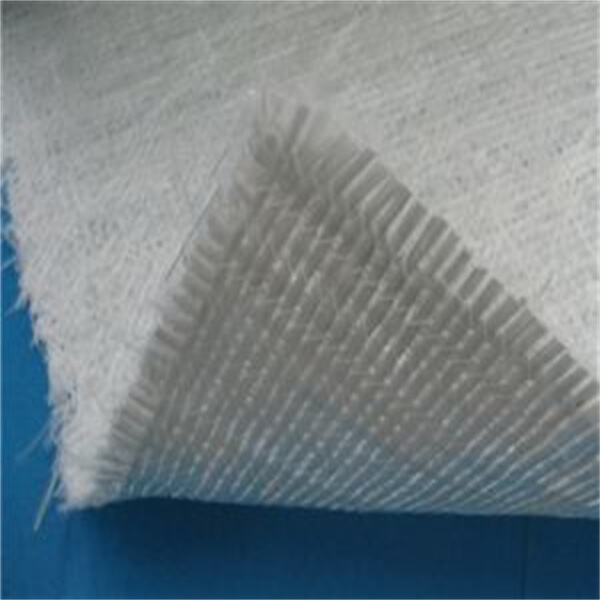

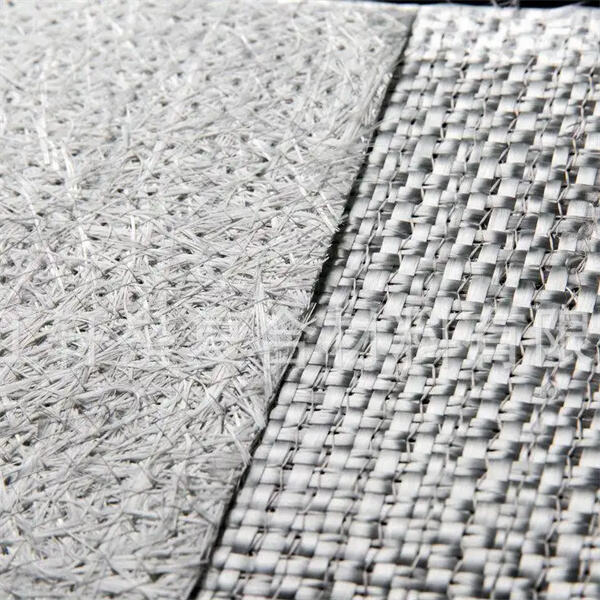

- You need to cut the fiberglass mat accurately as needed.

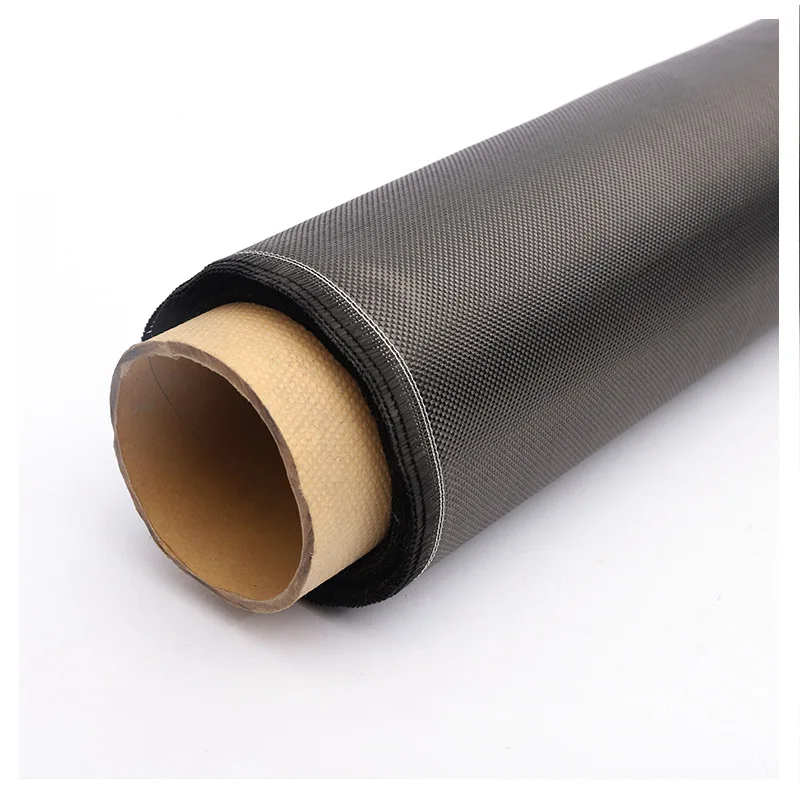

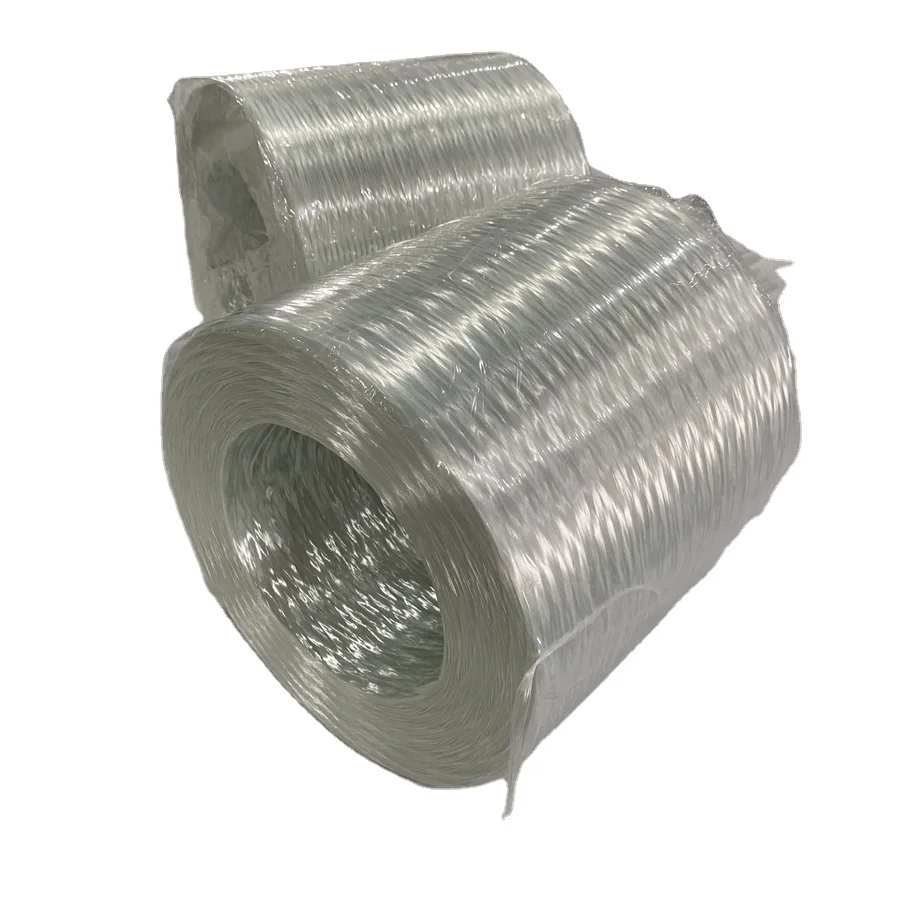

- Stir fiberglass resin and catalyst together per the manufacturer documentation for best results, as well as the AMP's carbon fiber fabric cloth.

- Evenly, apply the prepared resin mixture over the surface using a roller or brush.

- Spread resin over the hole and carefully lay a fiberglass mat on top, un-wrinkling it as you slowly push down to remove air bubbles. The weight of an automotive or fiberglass roller can help flatten out that material against your underlying panels for strong adhesion at this point too even better.

- Apply another layer of the resin mix over this top side to give it added strength and longevity.

- To grant this bond and finish we need to let the resin cure for its designated timeencia, how long is provided in the instructions given on use.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ