What Is Fiberglass Sleeving?

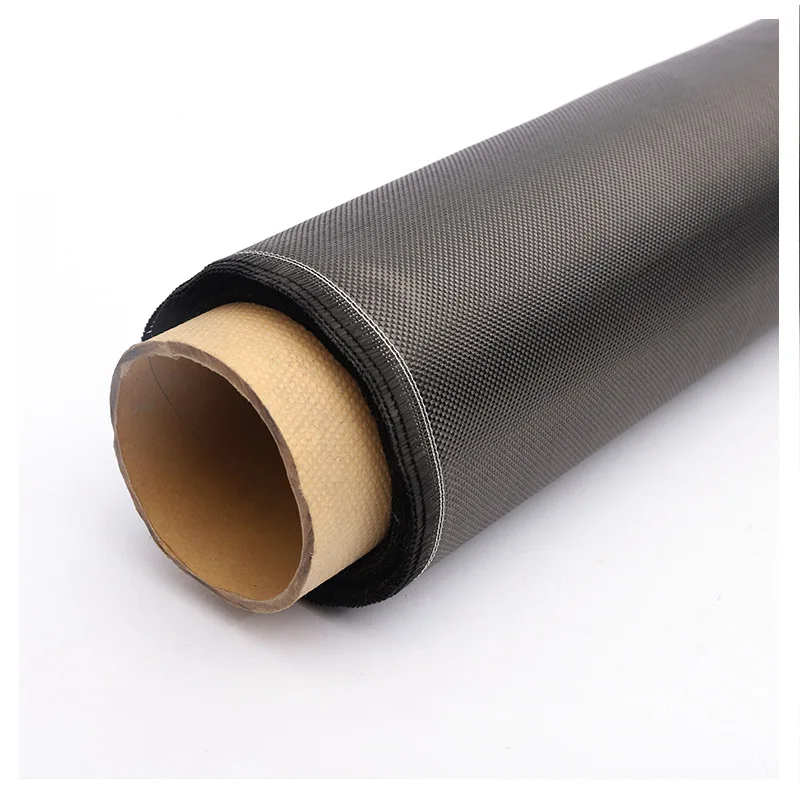

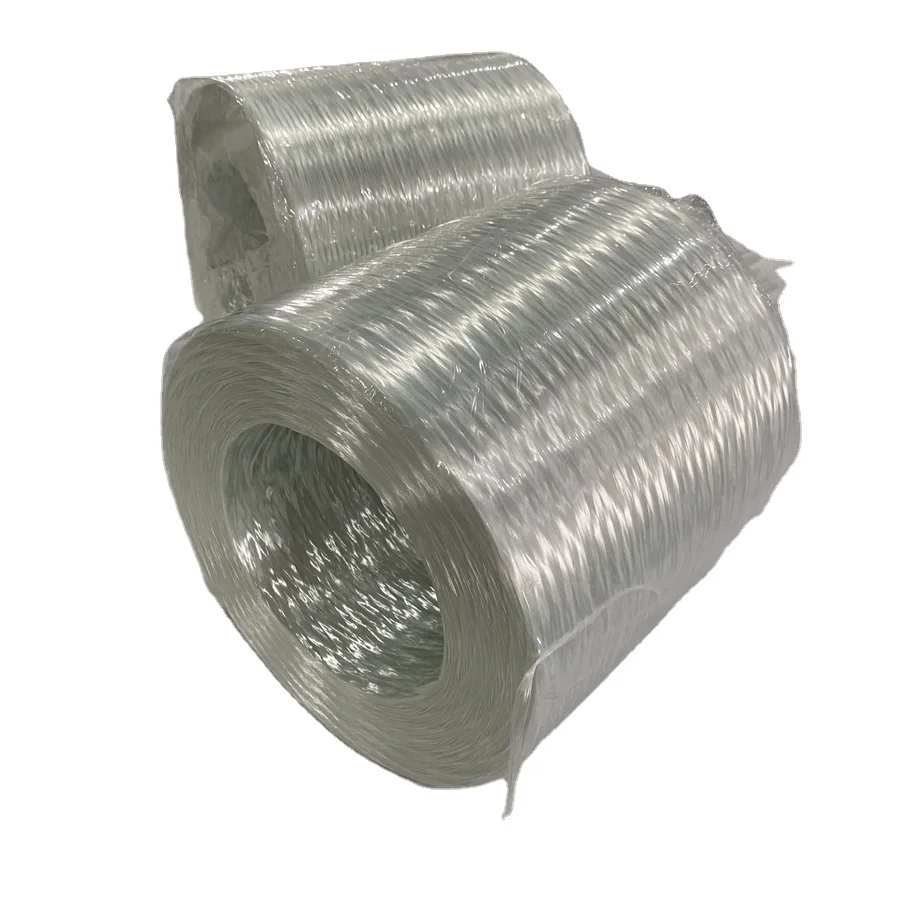

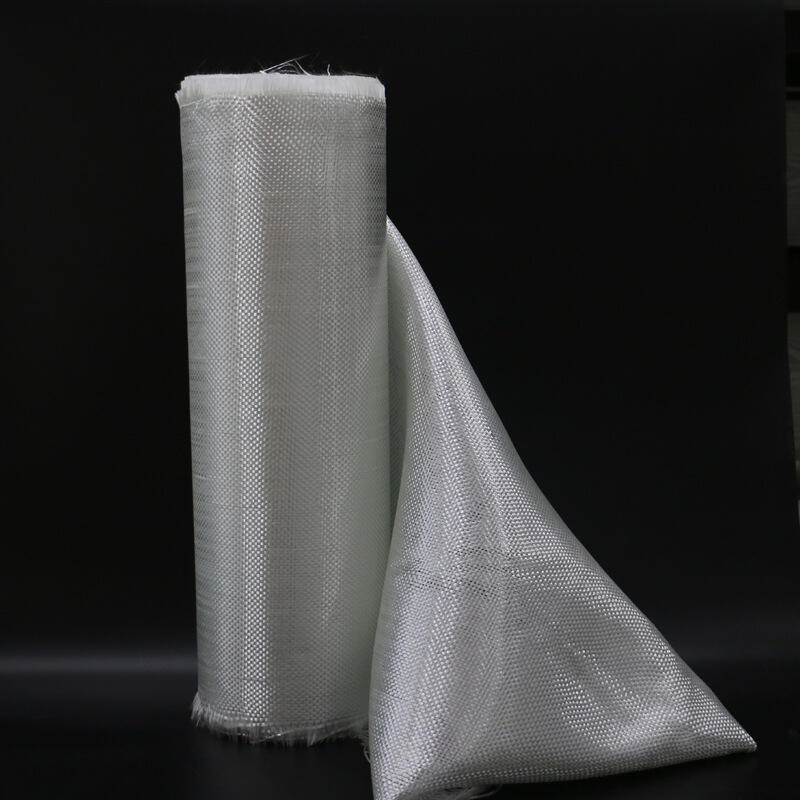

Fiberglass Sleeving is an important protective material employed to shield wires and cables. Its been made by weaving fiberglass yarn and then coating it with resin to make AMP 2x2 twill carbon fiber both flexible along with the durability factor. This material is fireproof, heat resistant and provides thermal protection of the wires it captures (and therefore electrical shocks).

BENEFITS OF FIBER GLASS SLEEVING

Fiberglass sleeving, you will find that there is a lot of usefulness in this type of unit. Chief among these is that it offers an extra level of protection for wires and cables from abrasion, chemicals, and heat. This reduces the number of times wires and cables are required to be maintained or replaced, thereby increasing their lifespan. In addition to this, the fact that it is non-flammable and does not releases toxic gases when exposed to high temperatures makes safer for use in hazardous environments.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ