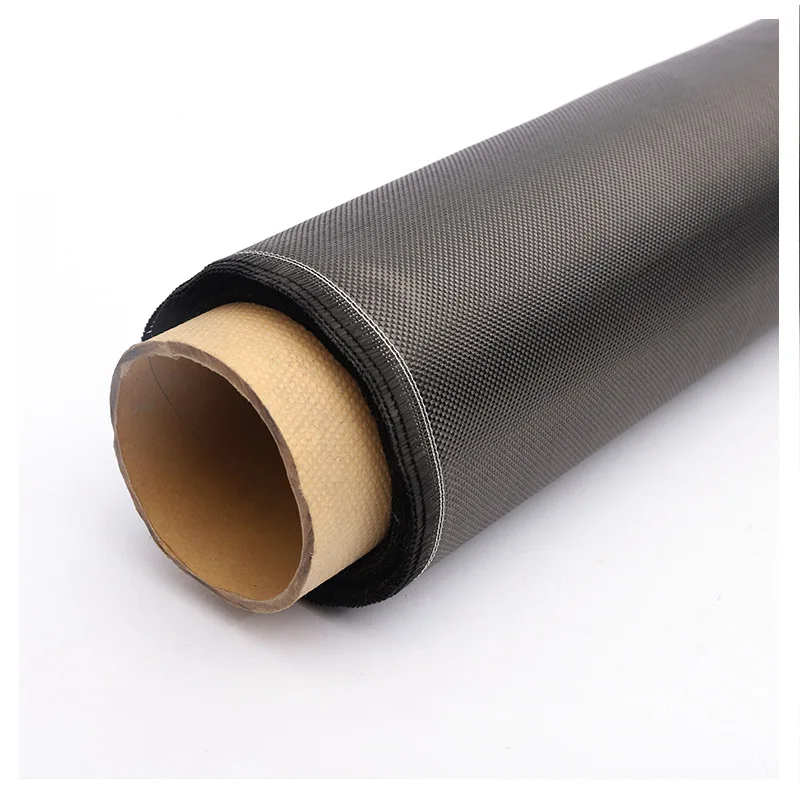

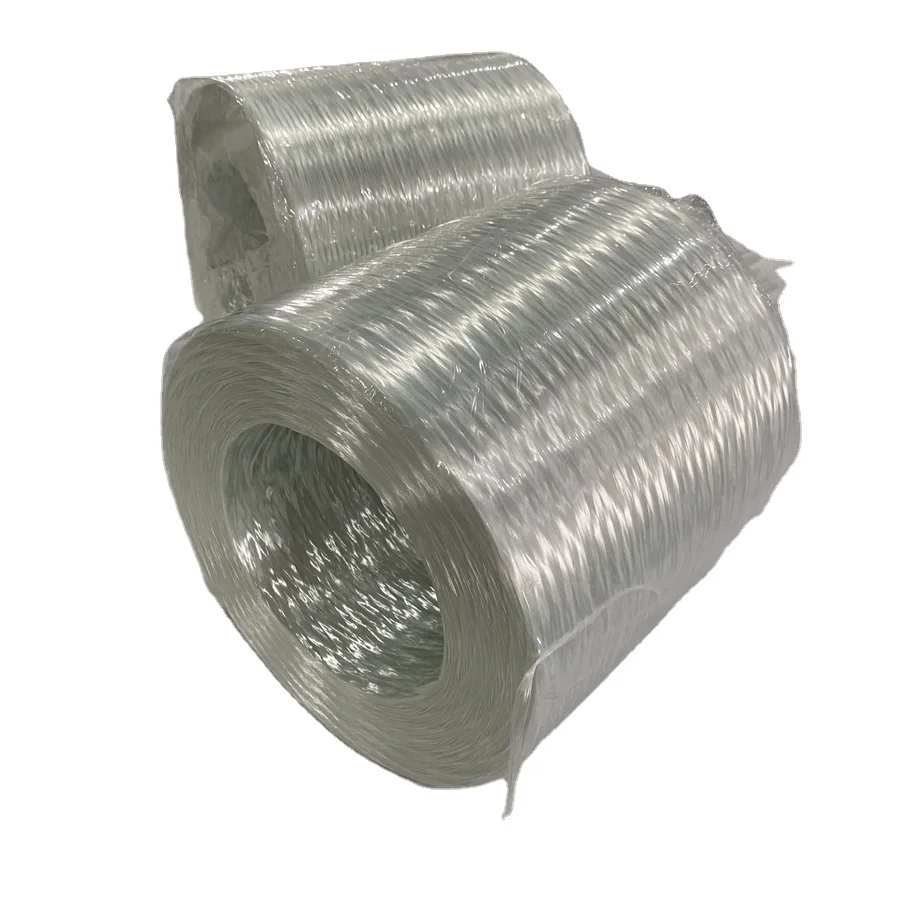

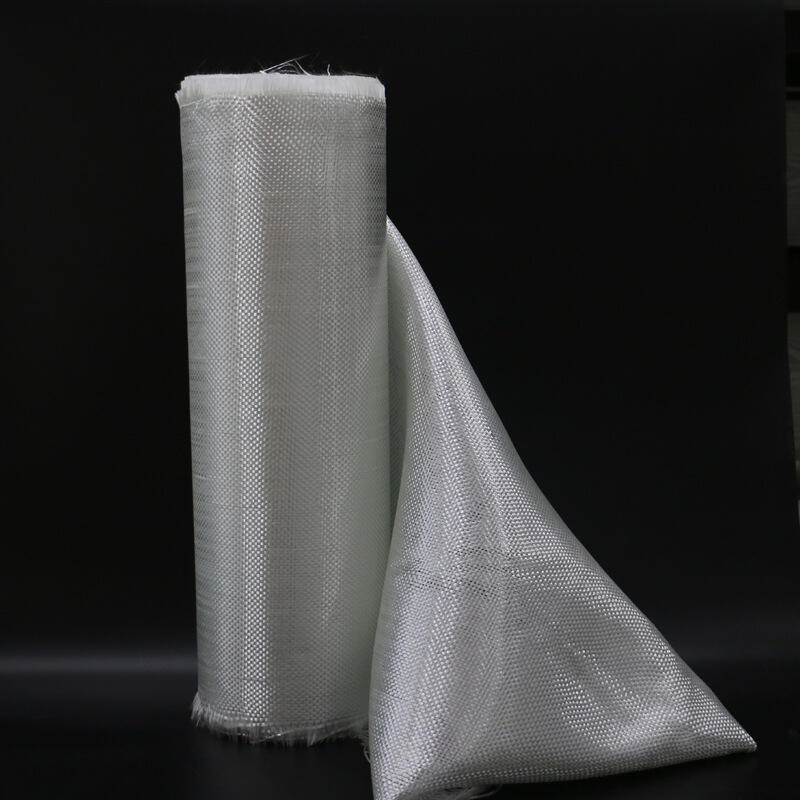

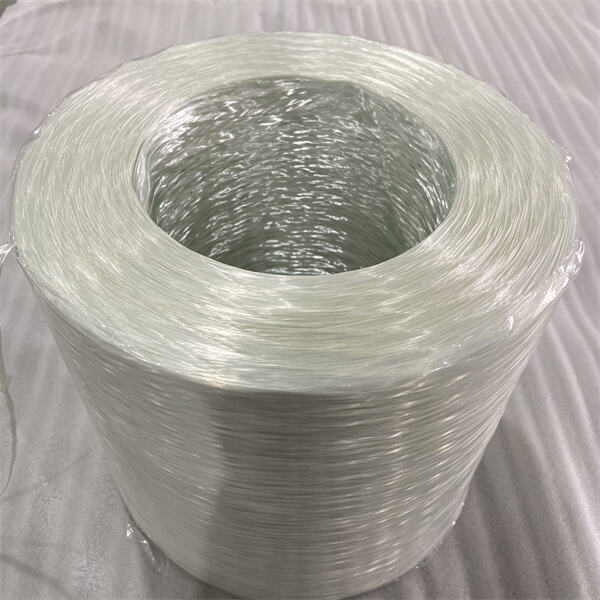

One of the most commonly used materials for projects that require high strength and durability is glass roving. This is a fiberglass material, which means it has been built to be strong and flexible using strands of fine glass fibers woven together. Glass roving is also favored in a variety of industries due to its high resistance to heat, corrosion and chemicals.

One of the remarkable strengths by glass roving have, is its ability to create safe and solid constructions able to withstand even substantial pressure. On the other hand, as its lifespan is longer and offers higher durability for applications that ask for a prolonged life.

Where urban roofing has surpassed simplicity in aesthetics and breathable, glass roving maintains its level of maturity even as manufacturers find new ways to apply this material in numerous applications across the many markets it serves. In the construction industry it is used to increase the tensile strength of materials such like concrete. It is involved in the development of wind turbine blades and has potential applications for automotive manufacturing that would produce lighter but stronger designs aimed at improving transportation system.

Glass Roving is very conformable with regard to safety when one touches and works by all means safely. It is safe as it gets: with no exposure to toxic chemicals and fume adjusters, AMP glass fiber roving offers a clean alternative for all kinds of customers. The superior chemical resistance allows for an added degree of reliability in this level, since safety-critical applications commonly use corrosion-resistant coatings.

Glass roving is simple to use. Select the proper amount for your application and measure roving with a ruler to that size. You can apply it right to any materials, no matter what shape they are, for an even more durable material or structural enhancement.

Quality services and support are of course crucial when working with glass roving, whether you're embarking on a large industrial project or just need some help around the house. When in doubt, professionals can help you choose the appropriate type and quantity of roving so that your project specifications are met.

Glass roving has various applications across the construction, and automation industry for improving structures as well to protect them from damages. A great solution for the production of corrosion resistant FRP components, glass fiber roving has an irreplaceable role in many areas like concrete structures or automotive parts. This leads to an improved behavior under high levels of cyclic loading, desired by all wind blade manufacturers.

Glass roving is flexible, resilient material with several applications as previously highlighted. You can find out more about how this chemically resistant material will help strengthen your project and keep it safe for a long, time to come!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ