Benefits of Woven Fabrics Uncovered

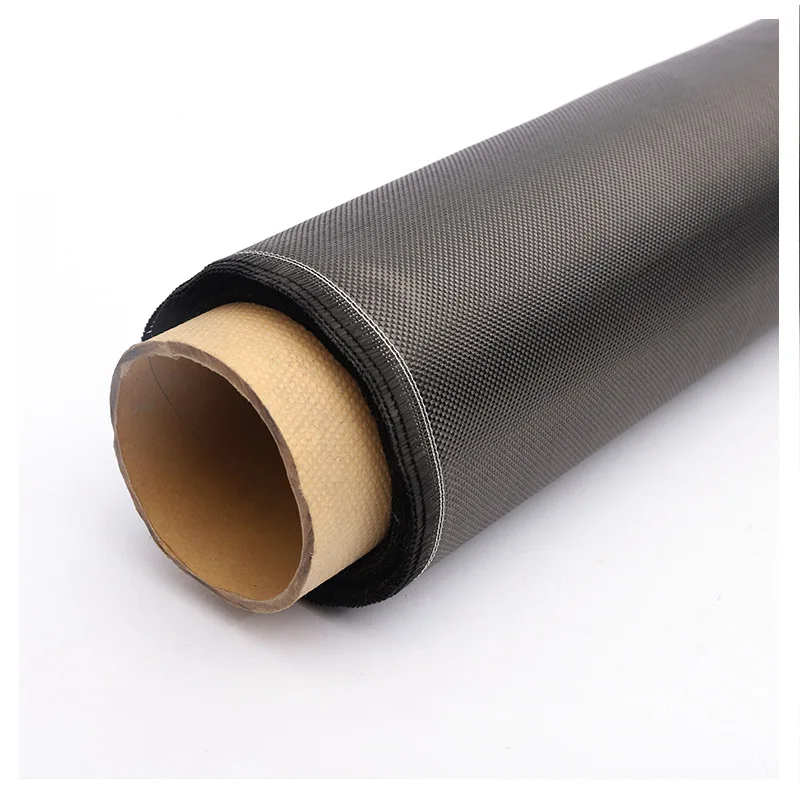

Long fiberglass strands are weaved through in a crisscrossed pattern which is what makes woven rovings so strong. All the benefits of strength and flexibility that 3D printing delivers refer directly to moving materials with high packed into a relatively lightweight size, so they do not need any specifics for shifting. Feather light compared to wound rovings, Lightweight woven rovings are still strong and stiff. Moreover, these substances are non-combustible materials that do not burn and 1000 only retains its form while providing heat or flames because they have a very high resistance properties to moisture, rusting and fire so you can use AMP woven roving for indoor uses including being used in building applications as outdoor.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ