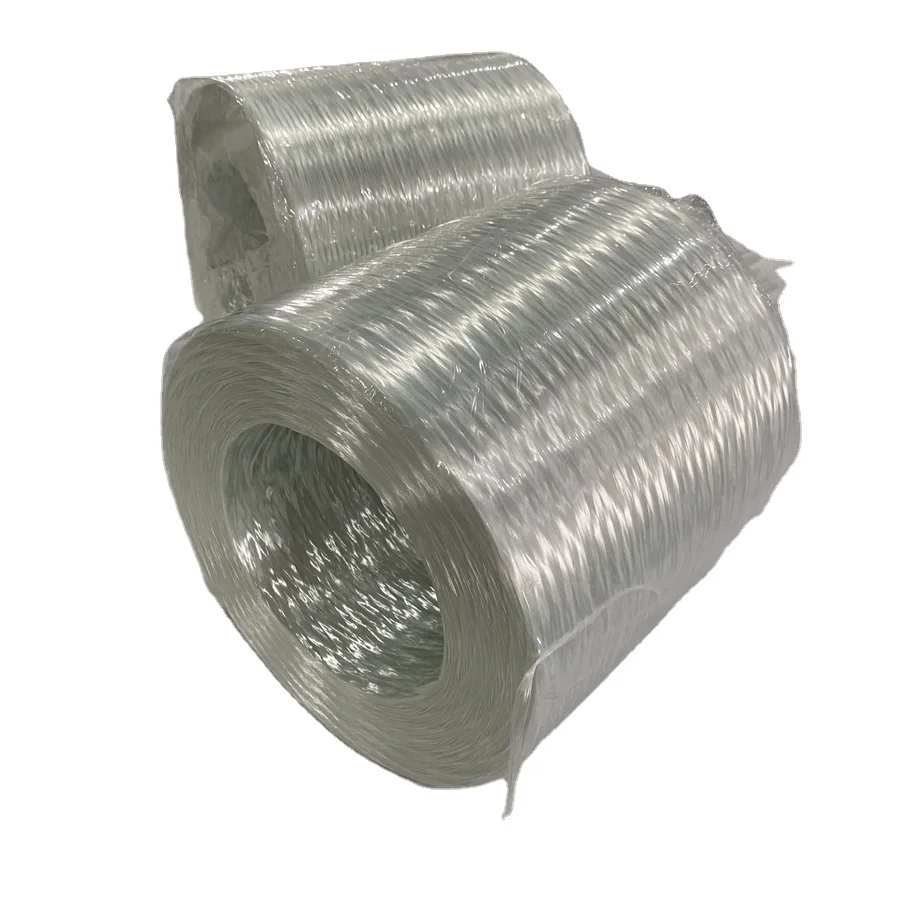

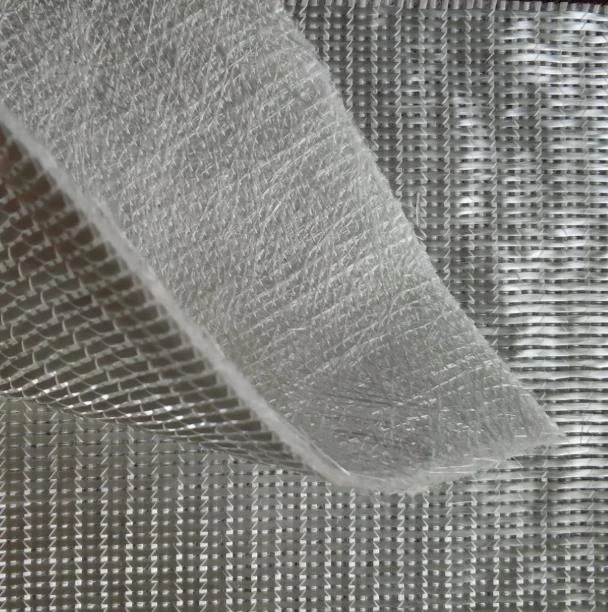

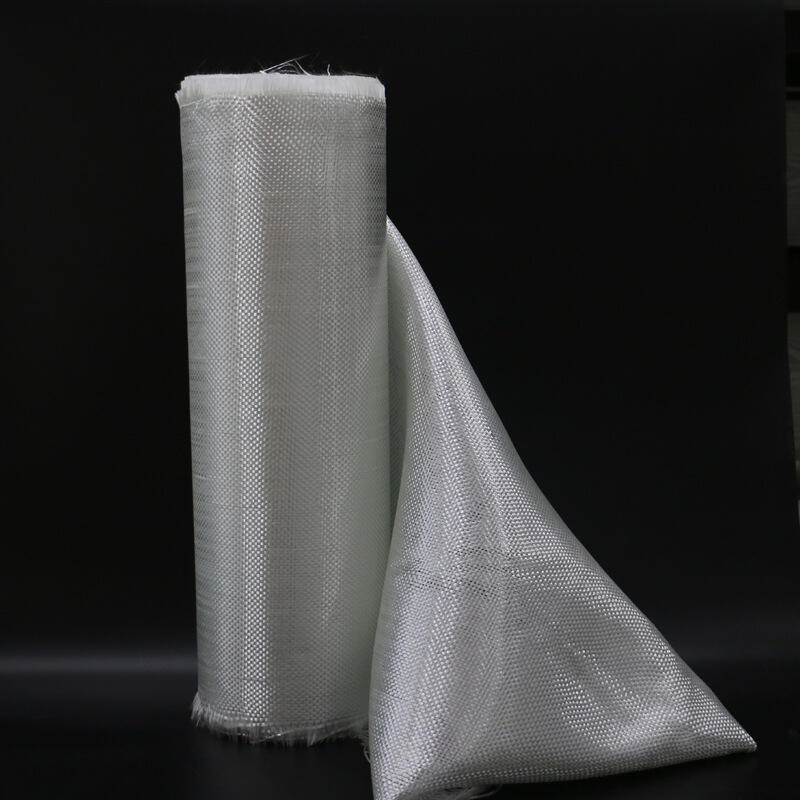

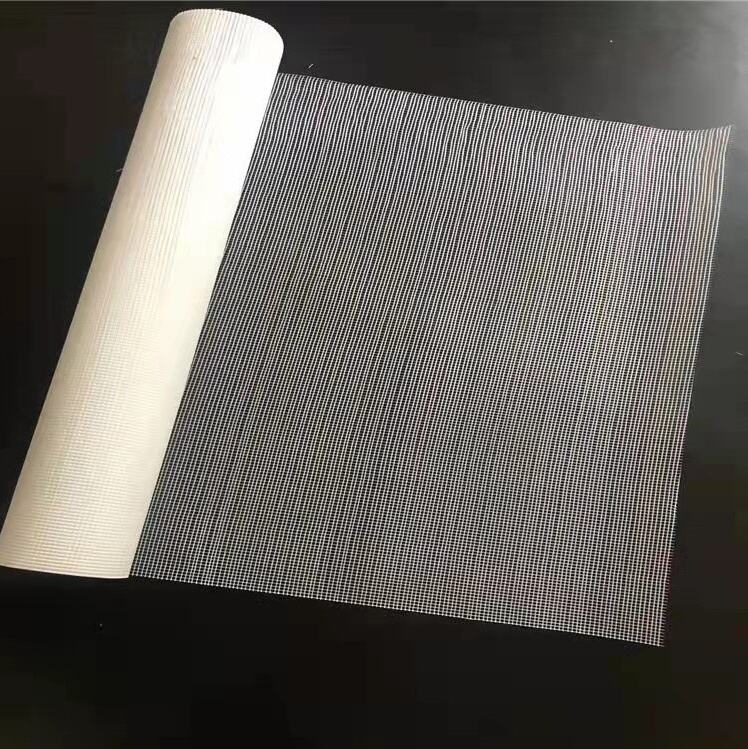

Boats are thrilling transports that skim the surface of the sea. They can lead us to fun places, like the beach or fishing trips! This is a beautiful process for making boats, but it can also be tricky and complicated. A really significant material used in boat making is fiberglass. This unique material is extremely common in boat building as it has a number of great properties. Fiberglass is created by melting glass and spinning it into exceptionally thin strings. These strands, finely woven together, become strong but light sheets, which can be used to make boats.

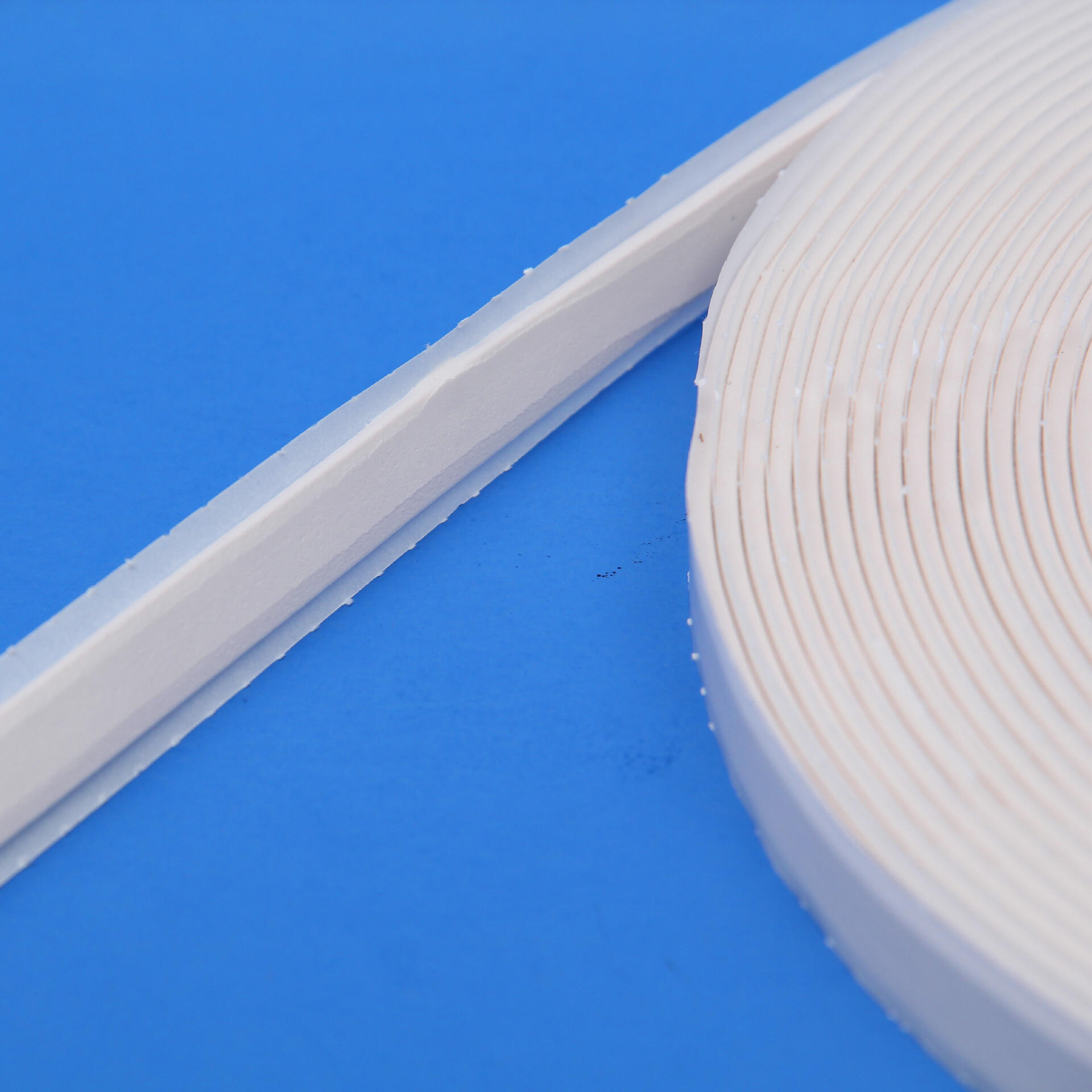

Fiberglass has several advantages, which make it a popular choice for boat construction. To begin with, it is lightweight, enabling boats to glide through the water. Second, it is strong, allowing boats made out of fiberglass to withstand rough conditions. Finally, fiberglass is long lasting, making it a superior choice than wood or metal for boatbuilding. This also means that boats built using fiberglass are strong and do not get damaged easily. It does not get damaged by water, rust, or sunlight. These properties mean fibreglass boats, with appropriate maintenance, tend to have a longer service life and require less maintenance than wooden or metal vessels.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ