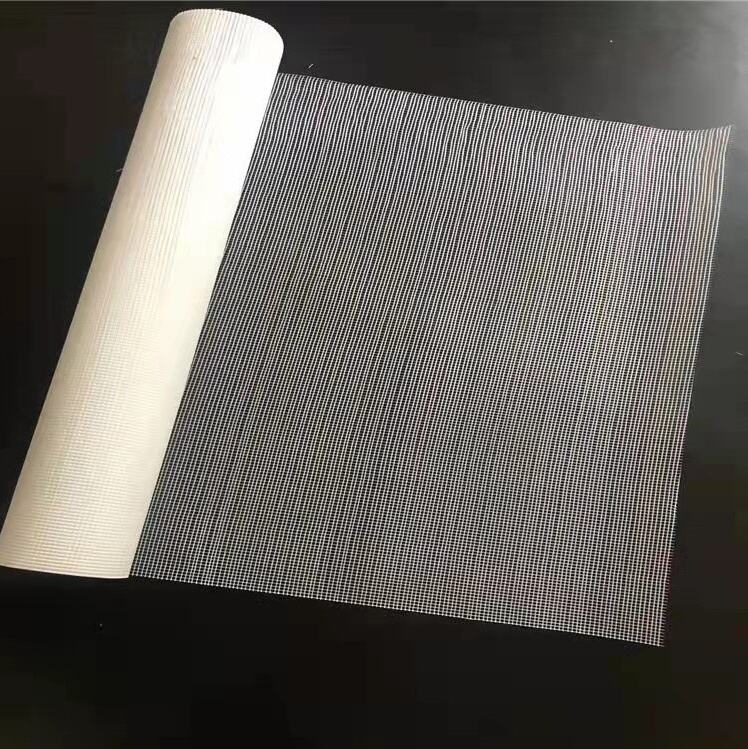

Fiberglass is a heavy-duty, useful material that so many individuals make use of in trade work. It is famous to be very useful in various industries that require specialized materials. AMP: One of the companies that specialize in fiberglass products. They have been at the forefront of this for years. Read on to find out what makes fiberglass an awesome pick for high-performance jobs and how it benefits industries.

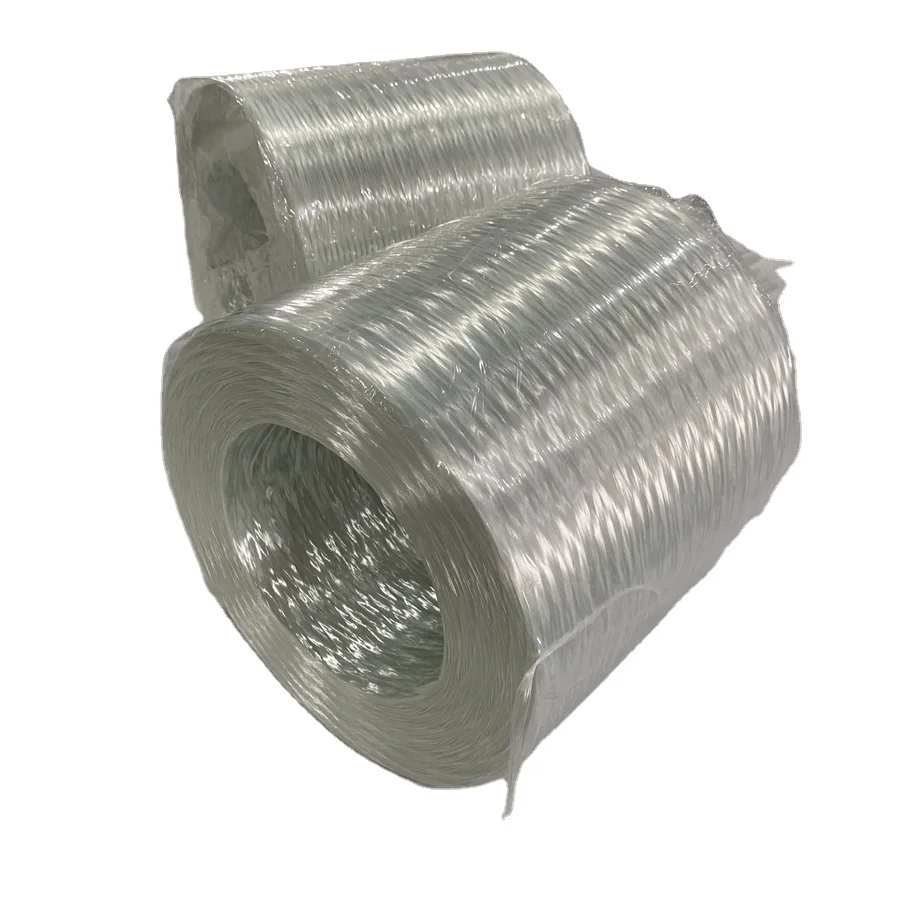

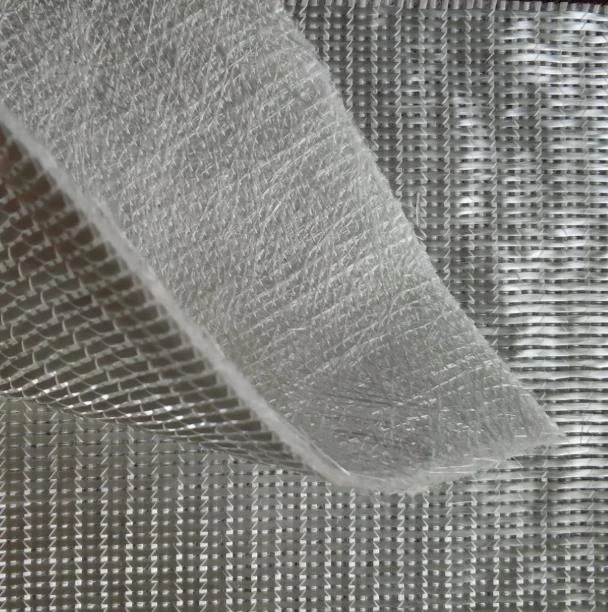

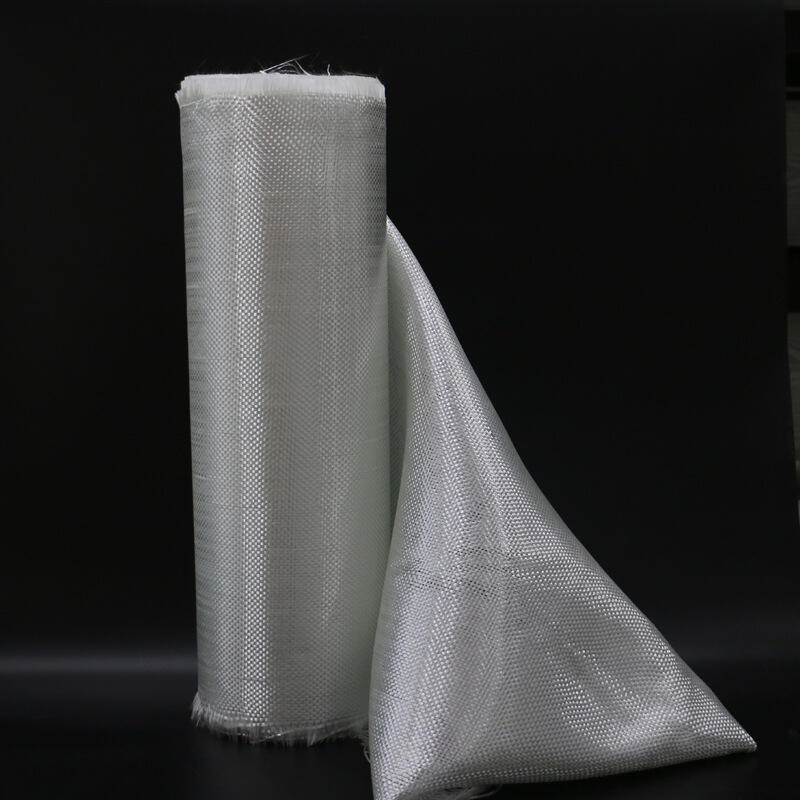

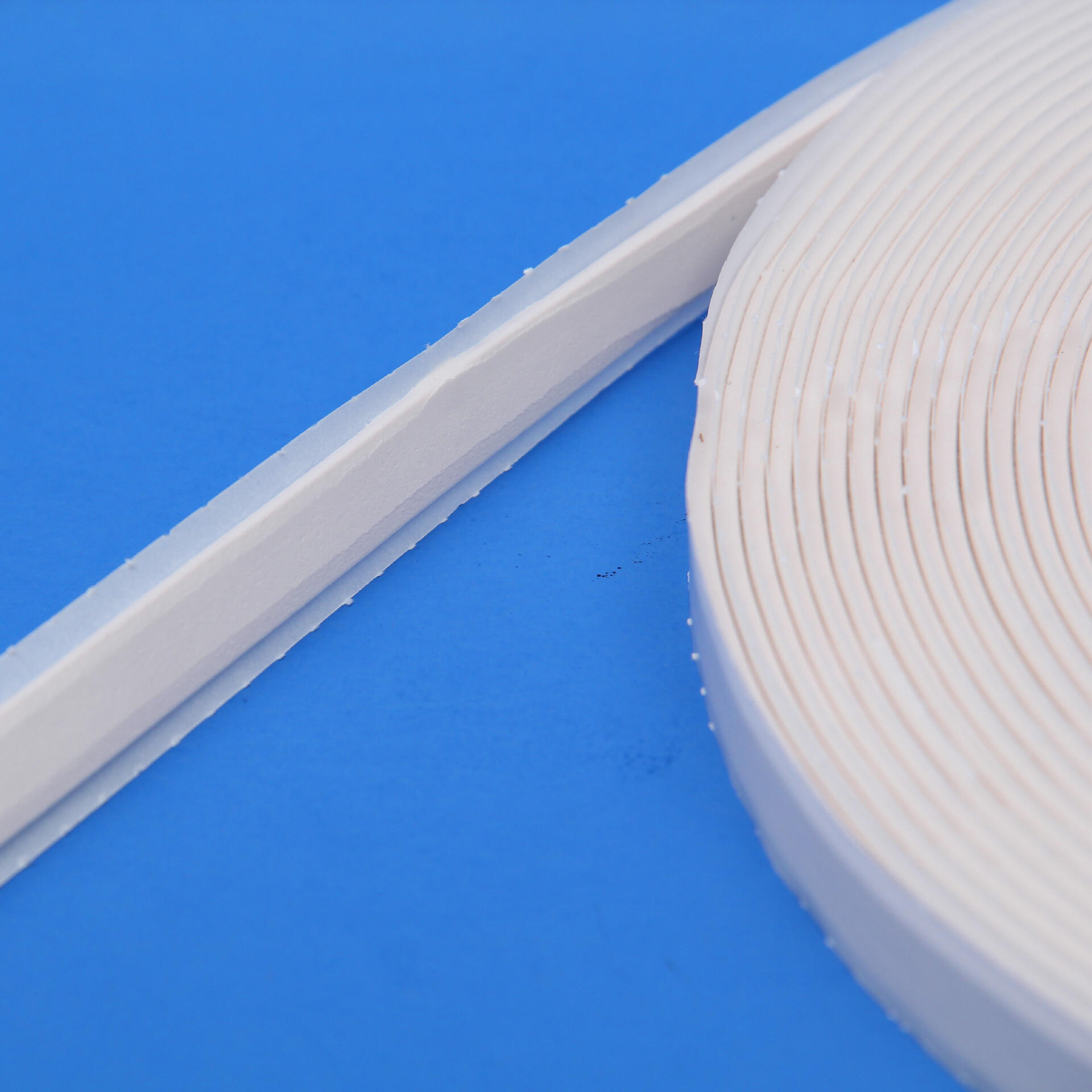

Fiberglass has multiple great features that make it a terrific material for vital tasks. It is strong, that is, it can withstand pressure. It is also lightweight, which makes it convenient to carry and pressure in a lot of uses. Also, fiberglass does not rust and is resistant to heat, making it more durable. This ensures it won’t come apart under strenuous conditions. Fiberglass can also be molded into various shapes, making it extremely versatile for a lot of applications. Due to high tensile strength, it can handle a strong pulling force without breaking. And that’s why fiberglass, with its constructive qualities, finds a perfect place in applications where strength and durability are crucial.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ