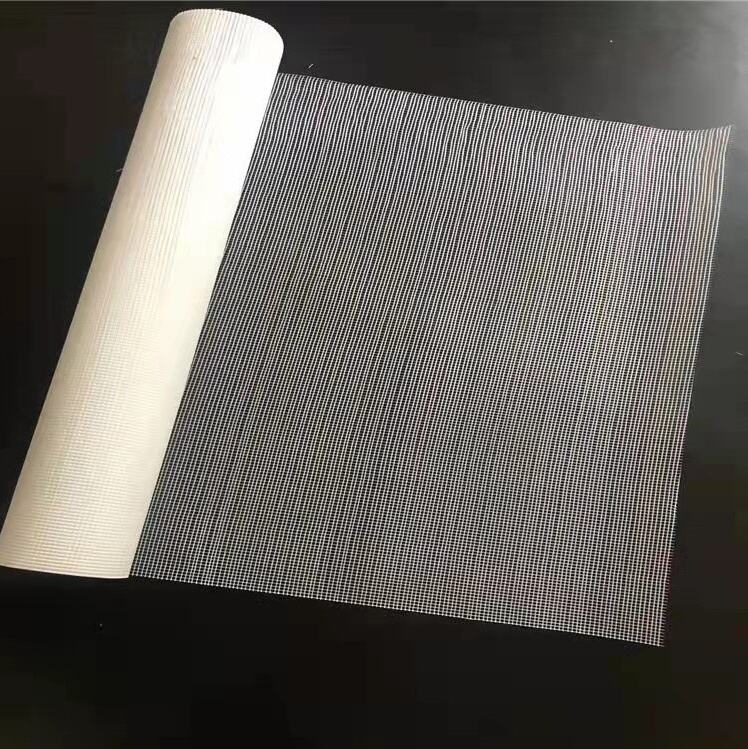

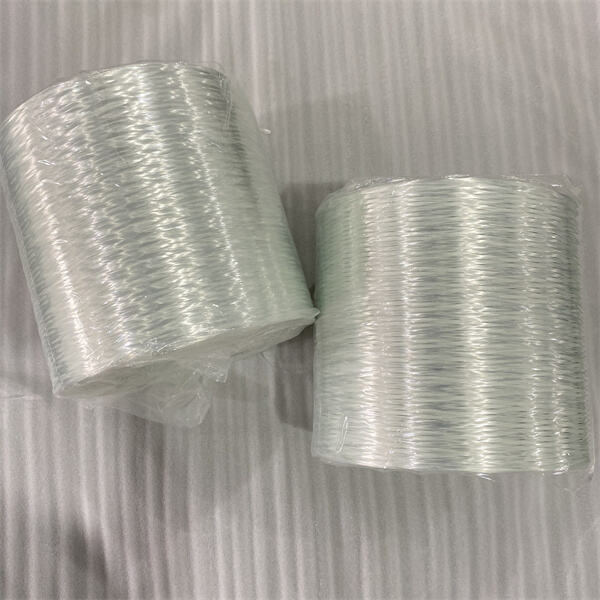

Harnessing the Power of Wind with Fiberglass Blade Technology

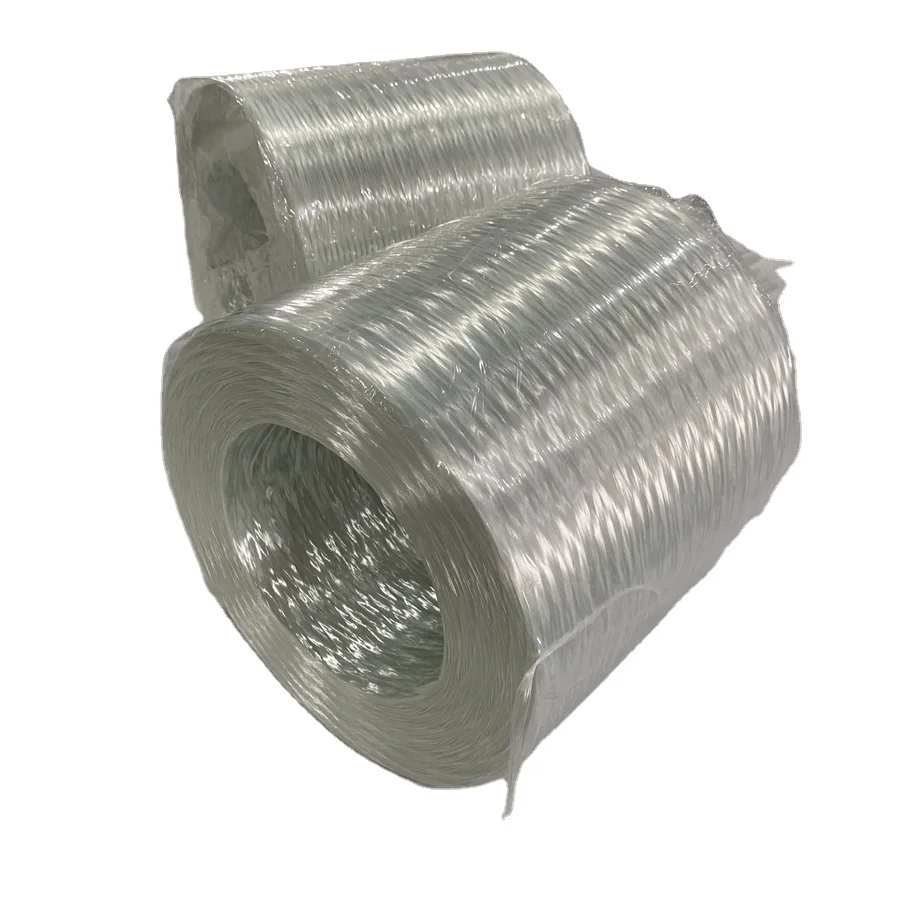

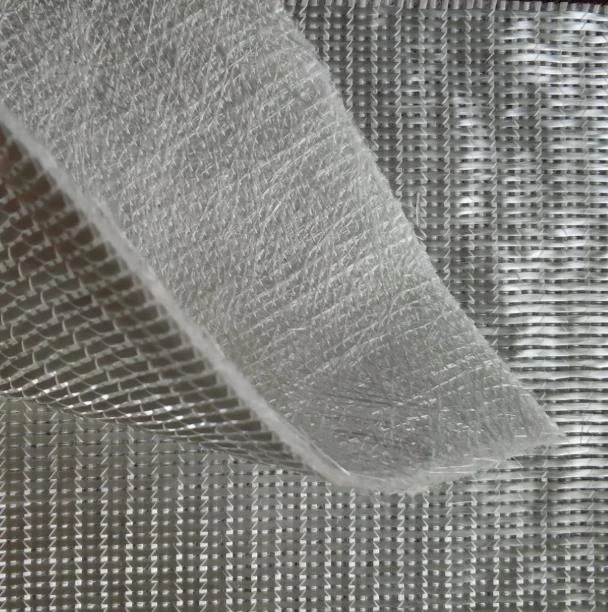

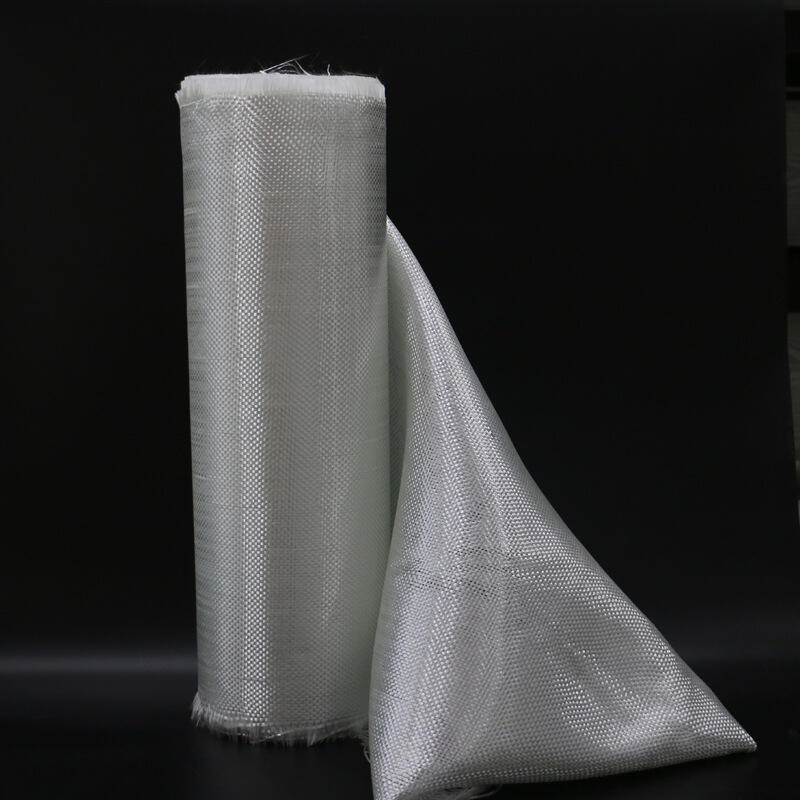

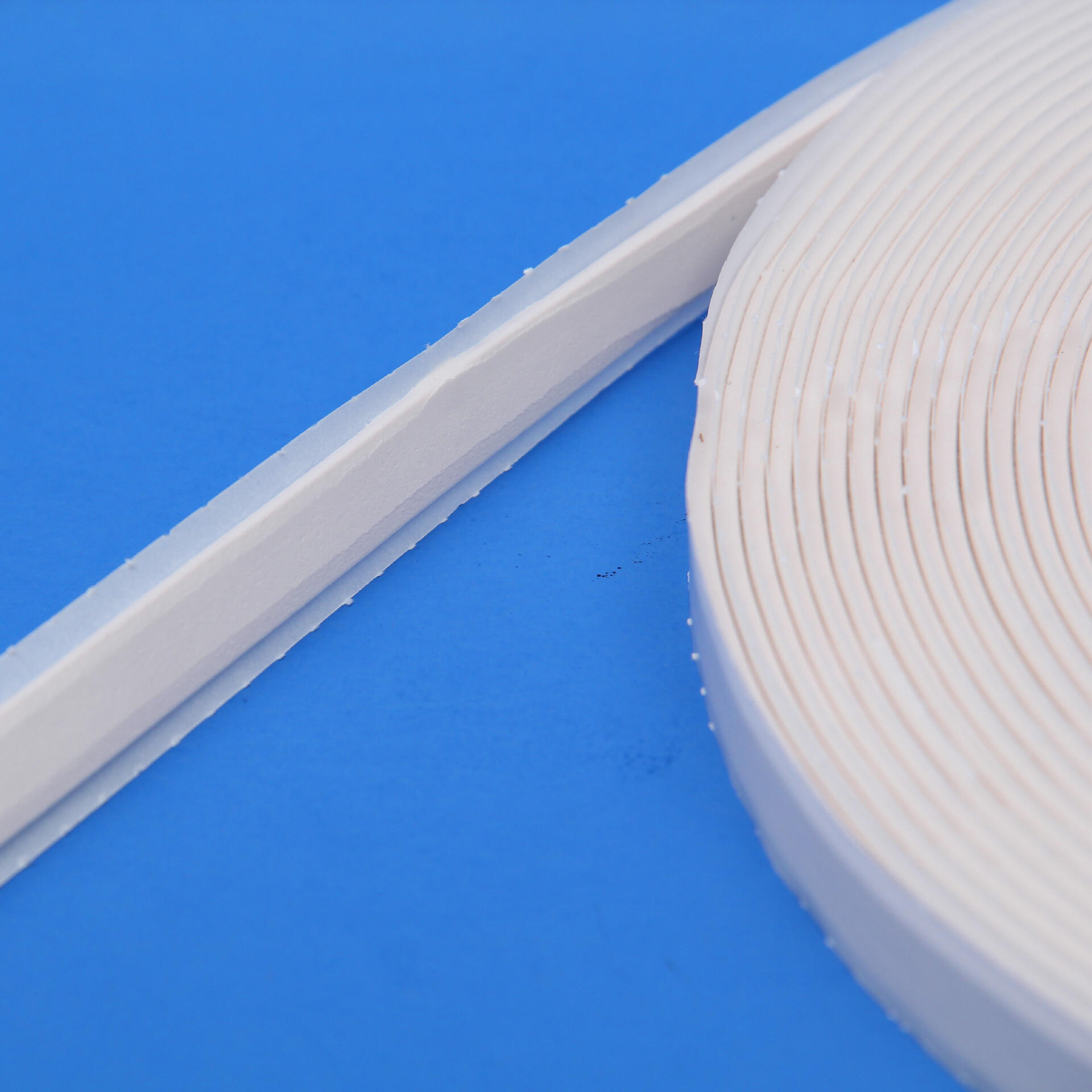

Fiberglass blades are really efficient in converting wind energy to power. That said, one of the reasons they are better than metal blades is that fiberglass blades can be forged longer. Longer blades catch more wind, which generates more electricity. At the same time fiberglass blades can be engineered to be more aero-dynamic, so they slice through air more cleanly. That means they can spin more easily in the wind and create even more energy, making them a great option for wind energy!

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ