Use

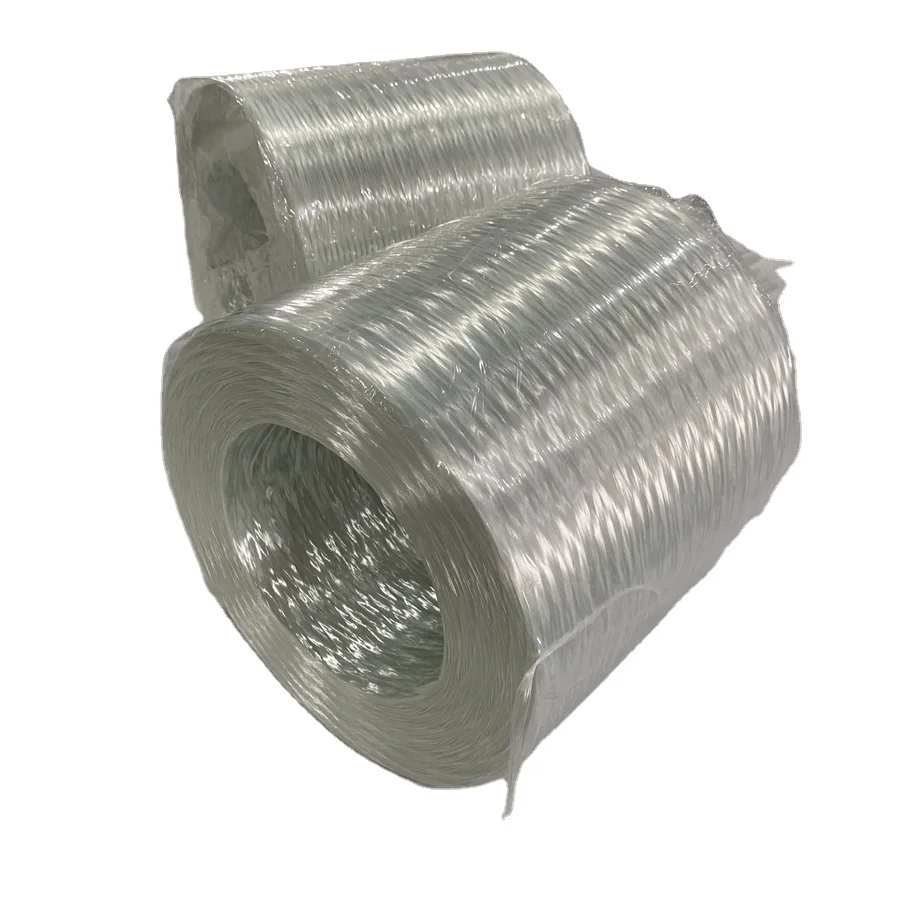

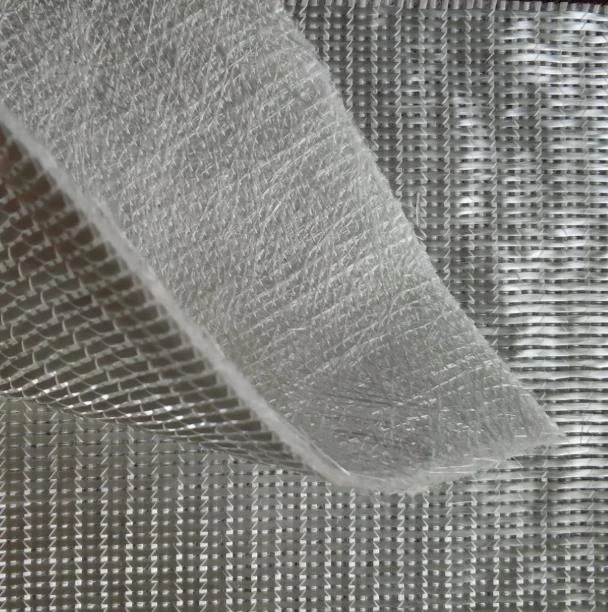

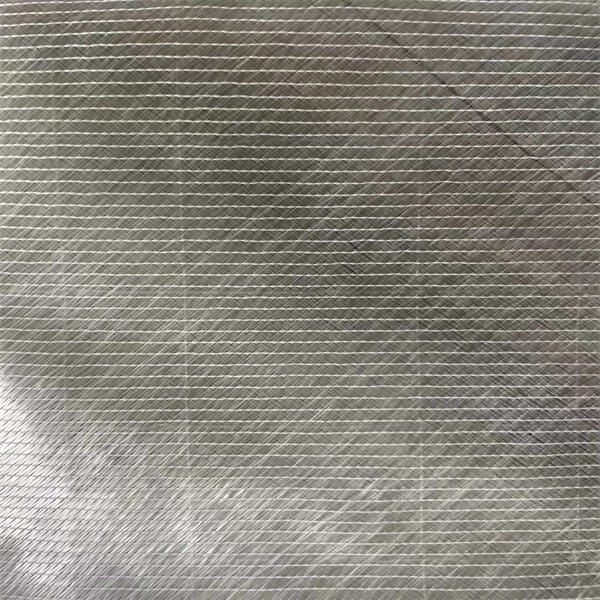

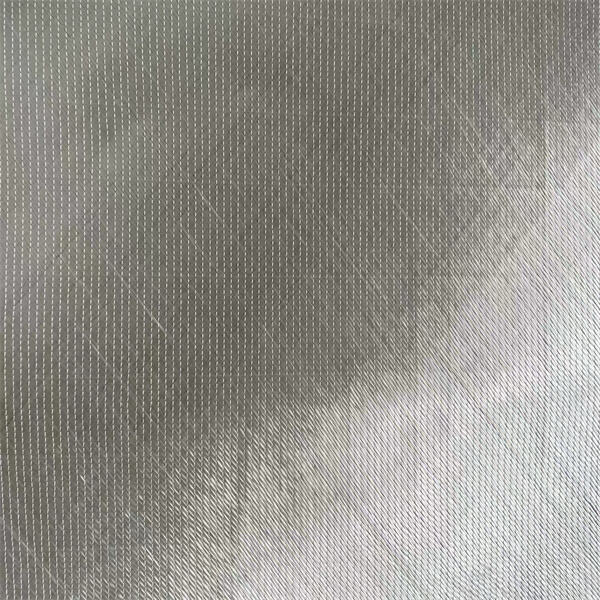

Fiberglass Triaxial Fabric is a very versatile material and has many uses mainly within boat building and aerospace to sports such as skis, snowboards etc. automotive industry; This fabric fiberglass gave it the status as a very mouldable materials that can be cut, formed to suit numerous wants.

How to Use

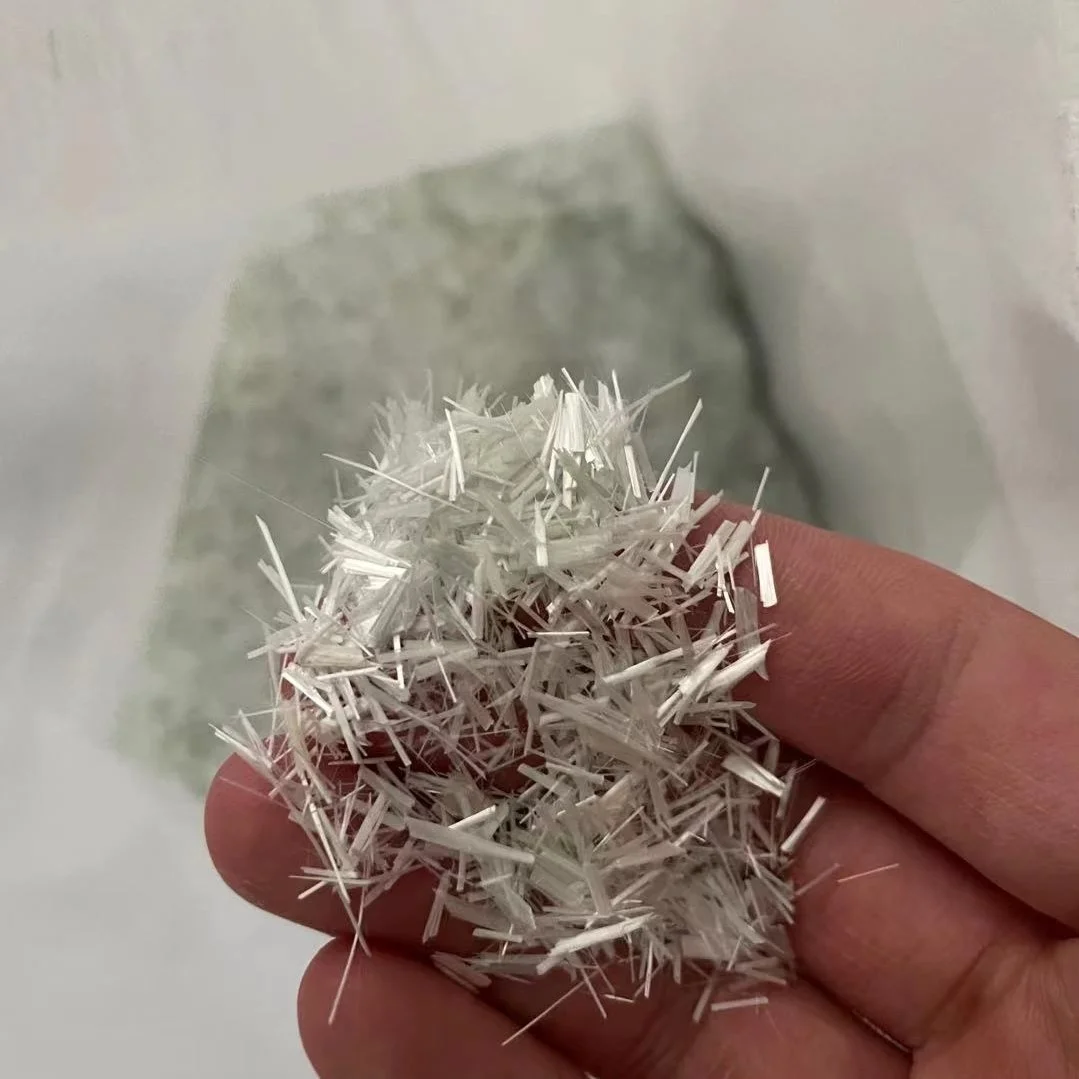

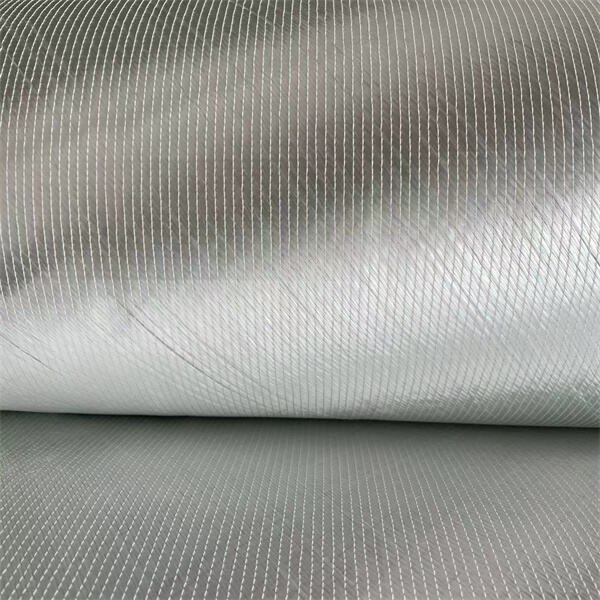

Safety of Fiberglass Triaxial Fabric The safety precautions for this substance are strict. Wearing protective equipment and using correct cutting and installation techniques to minimize risk. The fabric is cut with utility knives or scissors, heat shaped into the desired mold and adhered using adhesives, sewing or stapling.

Service and Quality

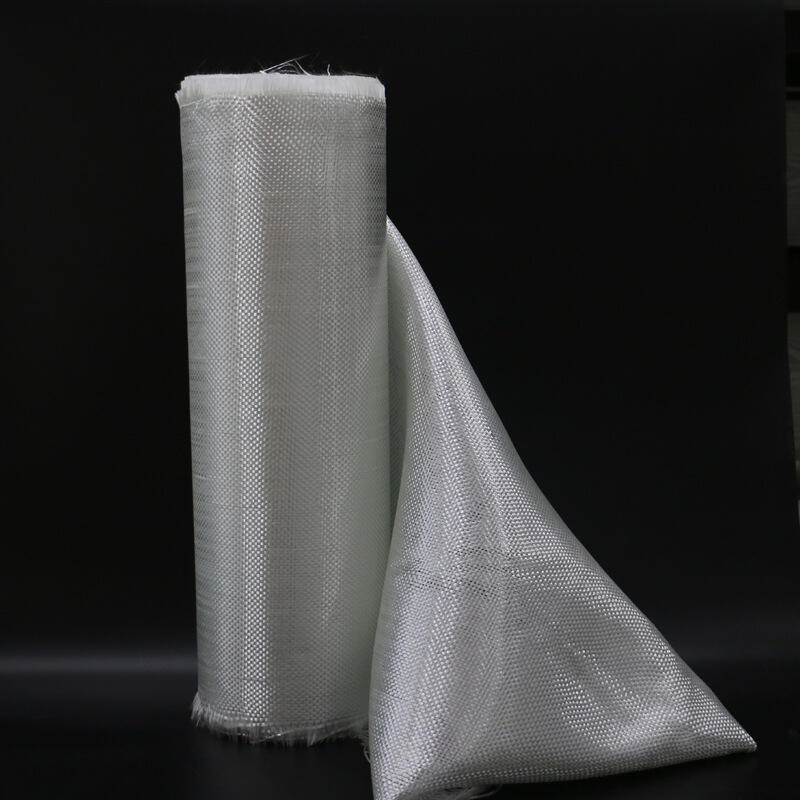

When it comes to the purchase of Fiberglass Triaxial Fabric, you need a supplier that provides quality materials and customer service. Look at suppliers who have plenty of satisfied customers, with a range of different sizes and styles in Fiberglass Triaxial Fabrics on offer - don't be afraid to question any available warranties or guarantees.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ