- Overview

- Inquiry

- Related Products

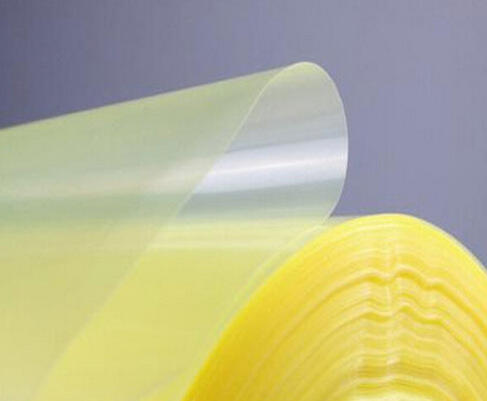

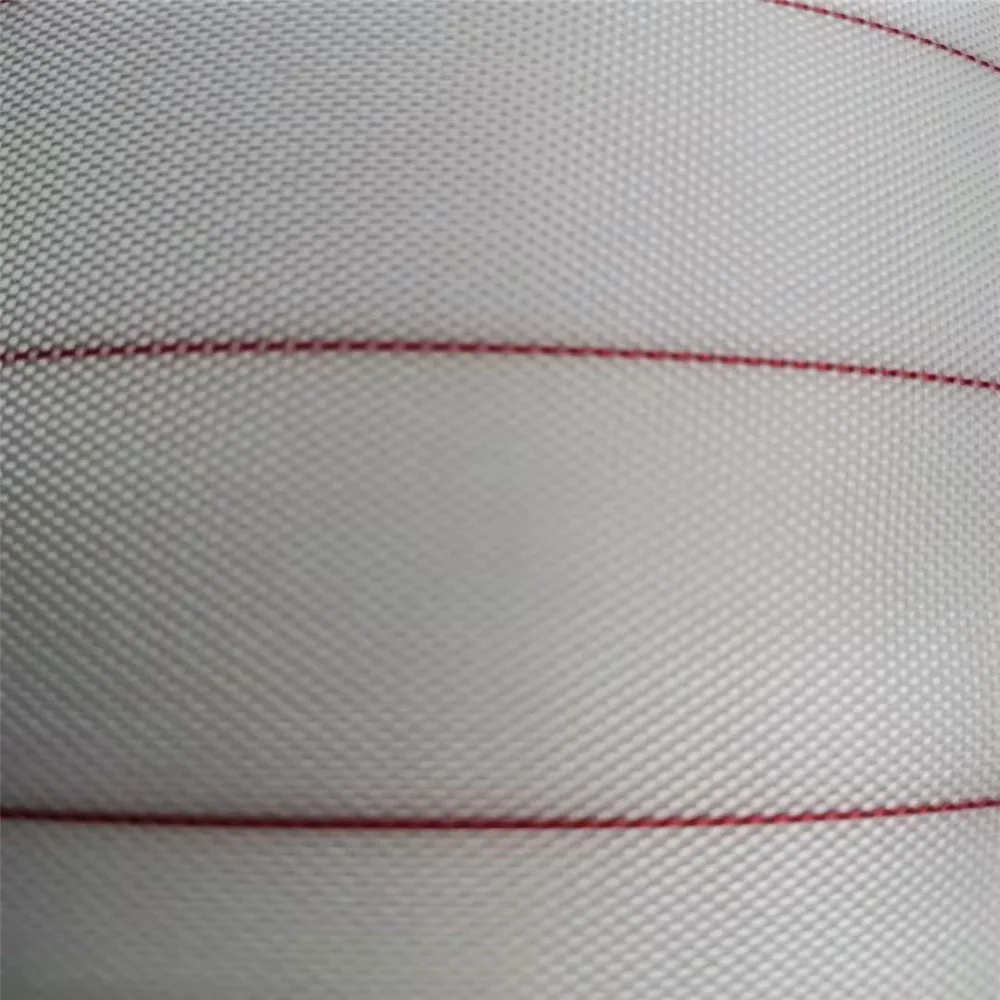

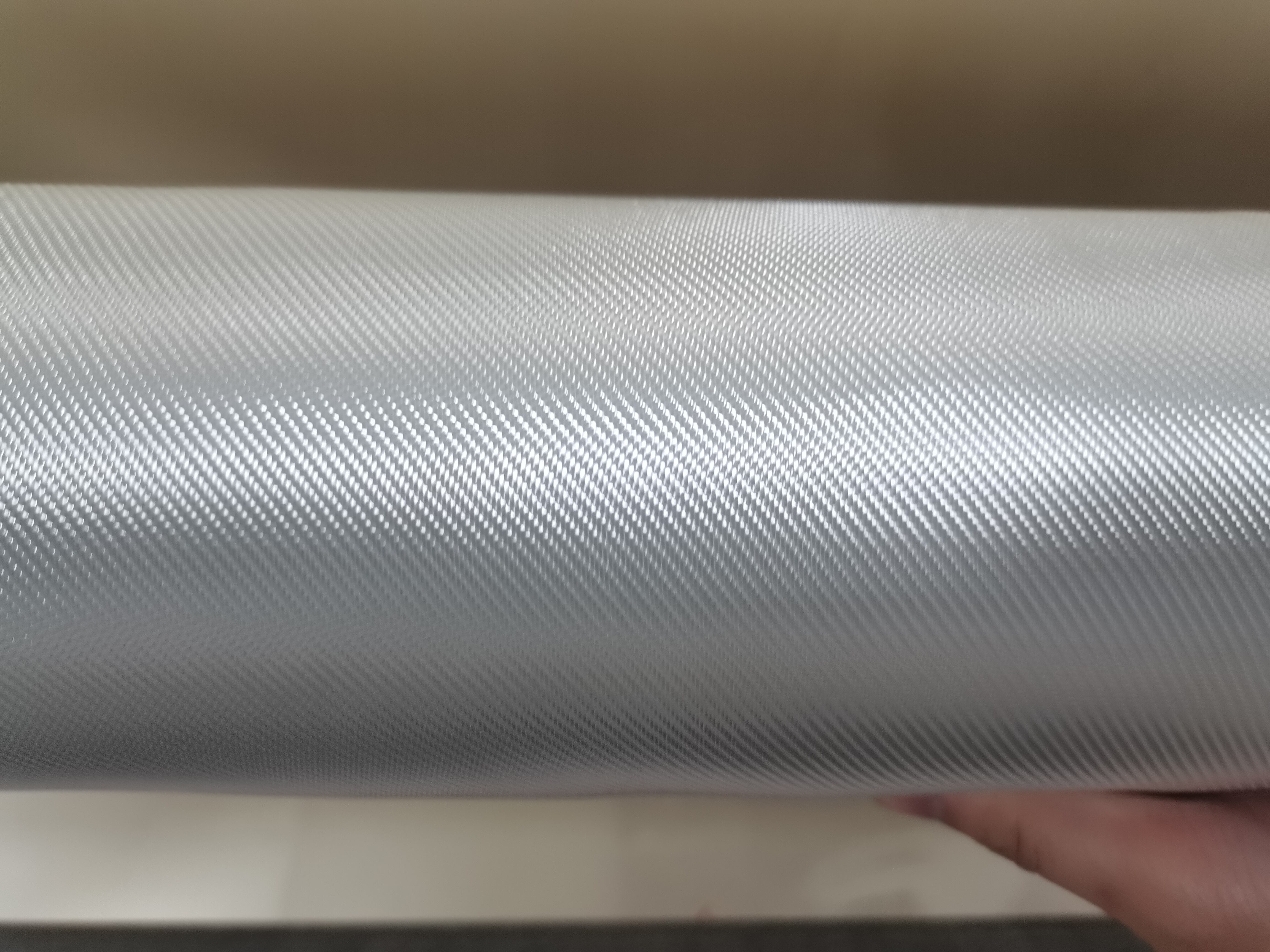

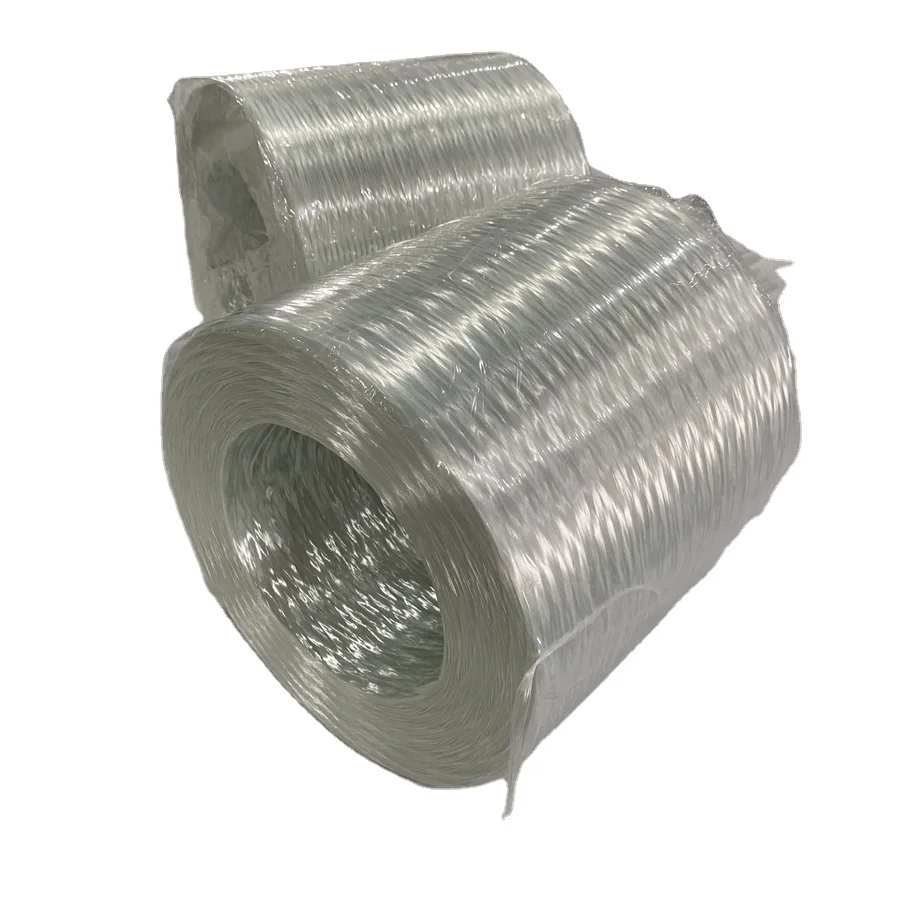

Bagging Film have high temperature resistant, it is one good material for Vacuum process products. Thickness can be from 50-80um and maximum width 12meters.It plays a crucial role in the fiberglass industry, especially in vacuum bagging processes used in composite manufacturing. It is essential for creating the necessary conditions for resin infusion and curing, ensuring uniform material properties and high-quality results.

Key Role in Vacuum Bagging Process

Creating a Vacuum Environment:Bagging Film is used to seal the mold and prepreg materials (such as fiberglass fabrics, woven cloth, or carbon fibers) in an enclosed space. By applying a vacuum, the air is extracted, creating a low-pressure environment. This helps ensure that resin is evenly infused into the fibers, which is essential for the final quality and strength of the composite material.

Uniform Resin Distribution:During the vacuum bagging process, the Bagging Film ensures that resin is uniformly absorbed into the fiberglass material, preventing issues such as air pockets, voids, or uneven curing. The right bagging film can help avoid these defects and ensure that the final product has the desired mechanical properties and appearance.

Accelerating Resin Curing:Bagging Film assists in accelerating resin flow and curing during the composite molding process. By creating a vacuum environment and applying heat, resin can quickly cure and fill the fiber spaces, improving production efficiency.

Preventing Air and Moisture Contamination

Prevents Air Entry:Bagging Film is airtight and prevents air from entering the sealed area. This is critical in ensuring that the composite material does not trap air bubbles or impurities during the molding process, which is especially important for high-performance composites used in industries like aerospace, automotive, and marine.

Moisture and Contaminant Protection:High-quality Bagging Film also prevents external moisture or contaminants from infiltrating the composite mold. This ensures the durability and corrosion resistance of the final product, which is particularly important in applications where the composite materials will be exposed to harsh environments.

Enhancing Molding Precision and Surface Quality

Provides Even Pressure:During the vacuum bagging process, the Bagging Film applies uniform pressure on the surface of the composite material, ensuring that the fiber layers are closely bonded with the resin. This helps eliminate air pockets and ensures that the surface of the composite is smooth and defect-free.

Improves Surface Finish:Bagging Film also helps achieve a smoother, higher-quality surface on the composite material. The film's flatness and smoothness contribute to the overall aesthetic quality of the product, reducing the likelihood of scratches or surface imperfections.

Other Applications

Resin Transfer Molding (RTM):In RTM, Bagging Film helps seal the mold and maintain negative pressure, aiding the resin injection process to flow smoothly into the fibers while minimizing defects such as air bubbles.

Pultrusion Process:Bagging Film is used in the pultrusion process to protect the material from contamination and ensure a smooth surface finish while maintaining the necessary vacuum conditions.

Key Considerations When Choosing Bagging Film

Thickness and Strength:The Bagging Film must have sufficient thickness and strength to withstand the high vacuum pressures without tearing or becoming damaged. A film that is too thin may rupture, while a film that is too thick could make resin infusion more difficult.

Temperature Resistance:During the curing process, the Bagging Film may be exposed to high temperatures. Therefore, it must be capable of withstanding the temperatures typically required in composite curing without degrading.

Breathability:Some types of Bagging Film are designed with micro-perforations to allow controlled airflow. This can be useful in certain processes to facilitate resin flow and prevent air bubble formation.

Chemical Compatibility:The Bagging Film must be compatible with the resin used, ensuring that it does not react with the resin or interfere with its curing process. Selecting a chemically resistant film increases the longevity and performance of the film in various applications.

In the fiberglass industry, Bagging Film is a vital material used in the composite molding process, especially in vacuum bagging. It plays a key role in creating the vacuum environment, ensuring uniform resin distribution, improving molding precision, and enhancing the surface quality of the composite. Additionally, it helps protect against contamination and moisture. Proper selection of Bagging Film is crucial for achieving high-quality composite materials, particularly in demanding applications such as aerospace, automotive, and marine industries. Its use directly impacts the efficiency of the molding process and the performance of the final product.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ