- Overview

- Inquiry

- Related Products

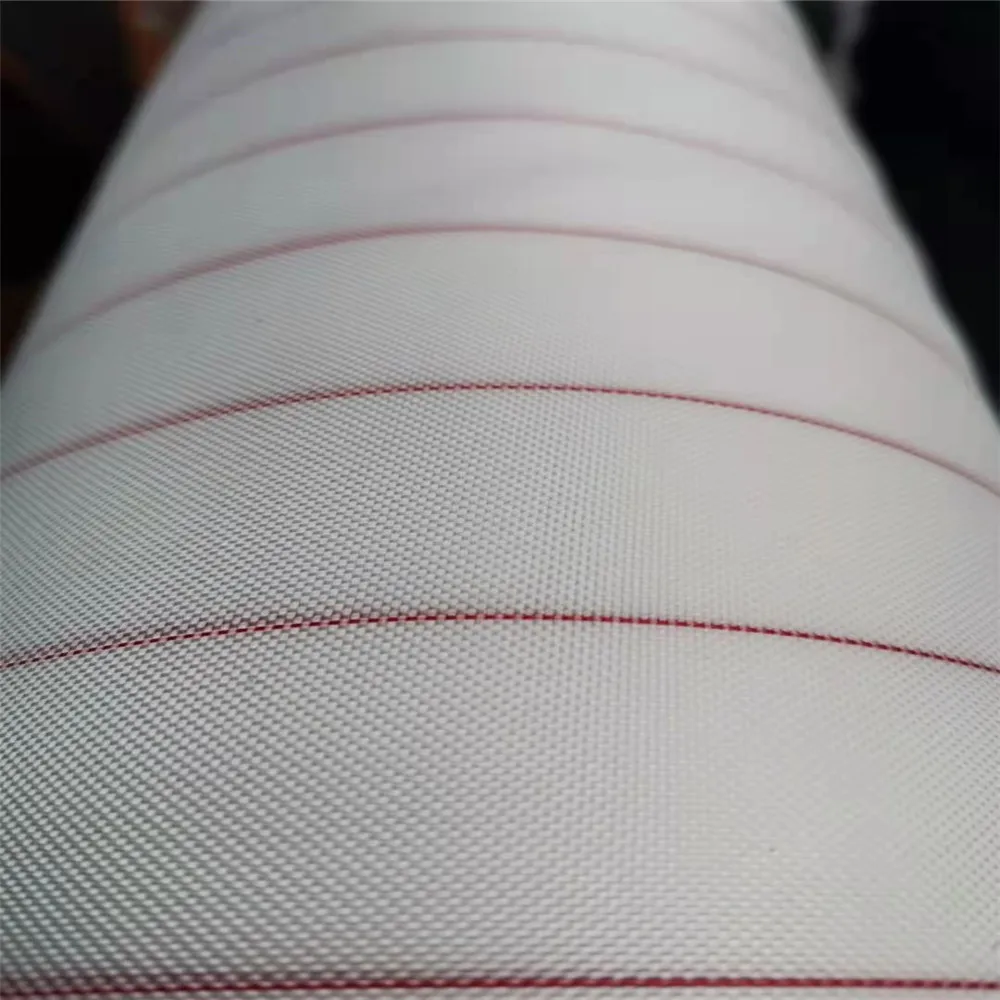

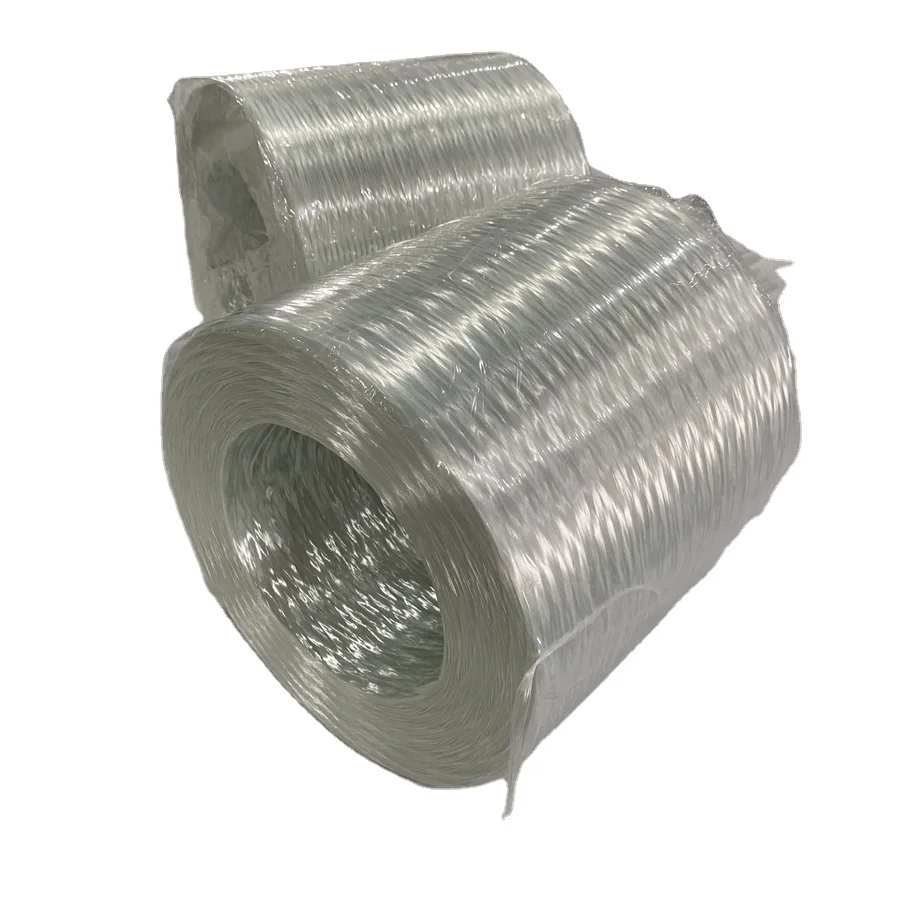

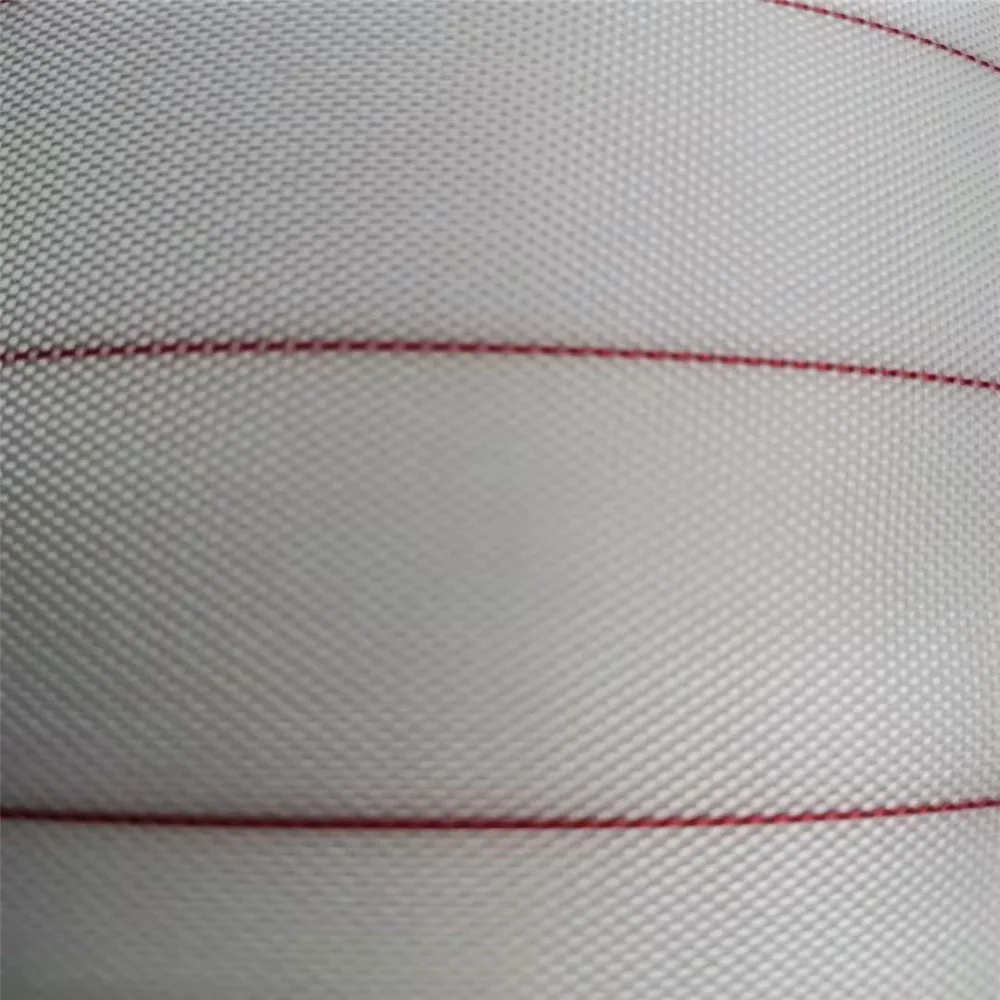

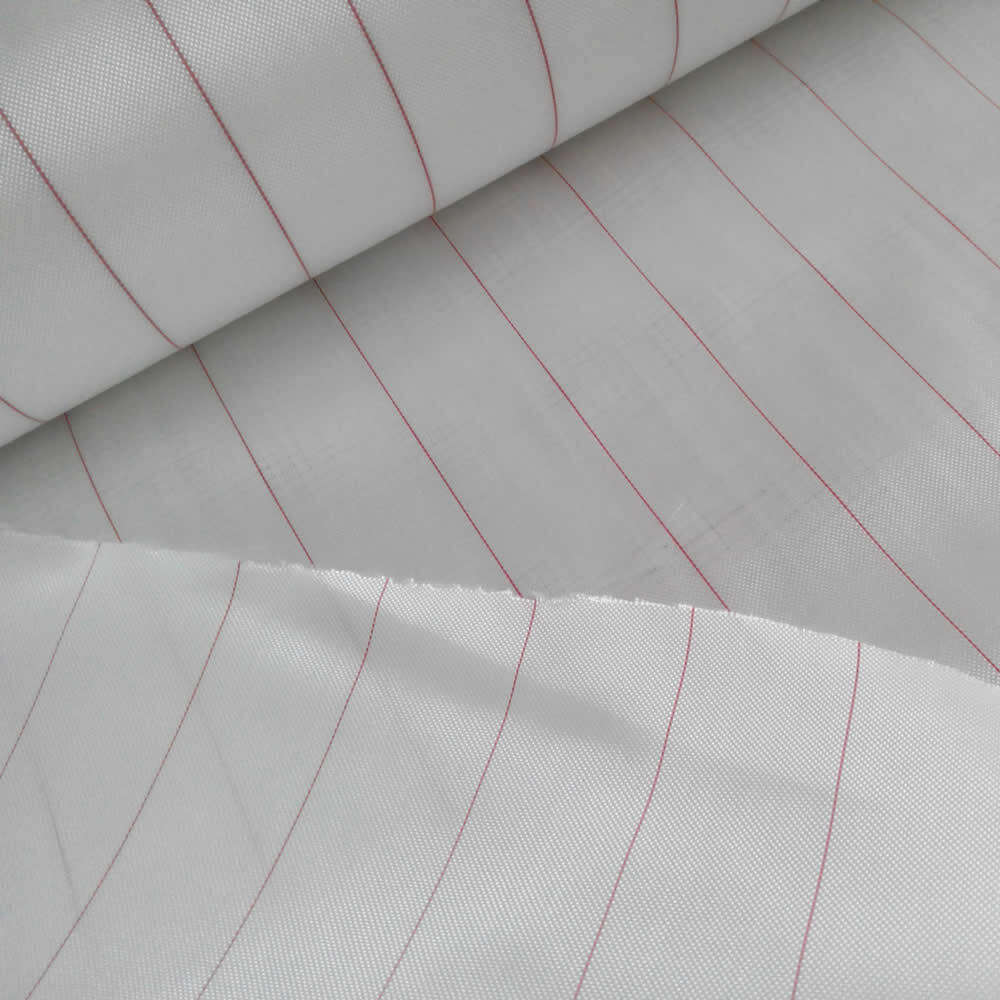

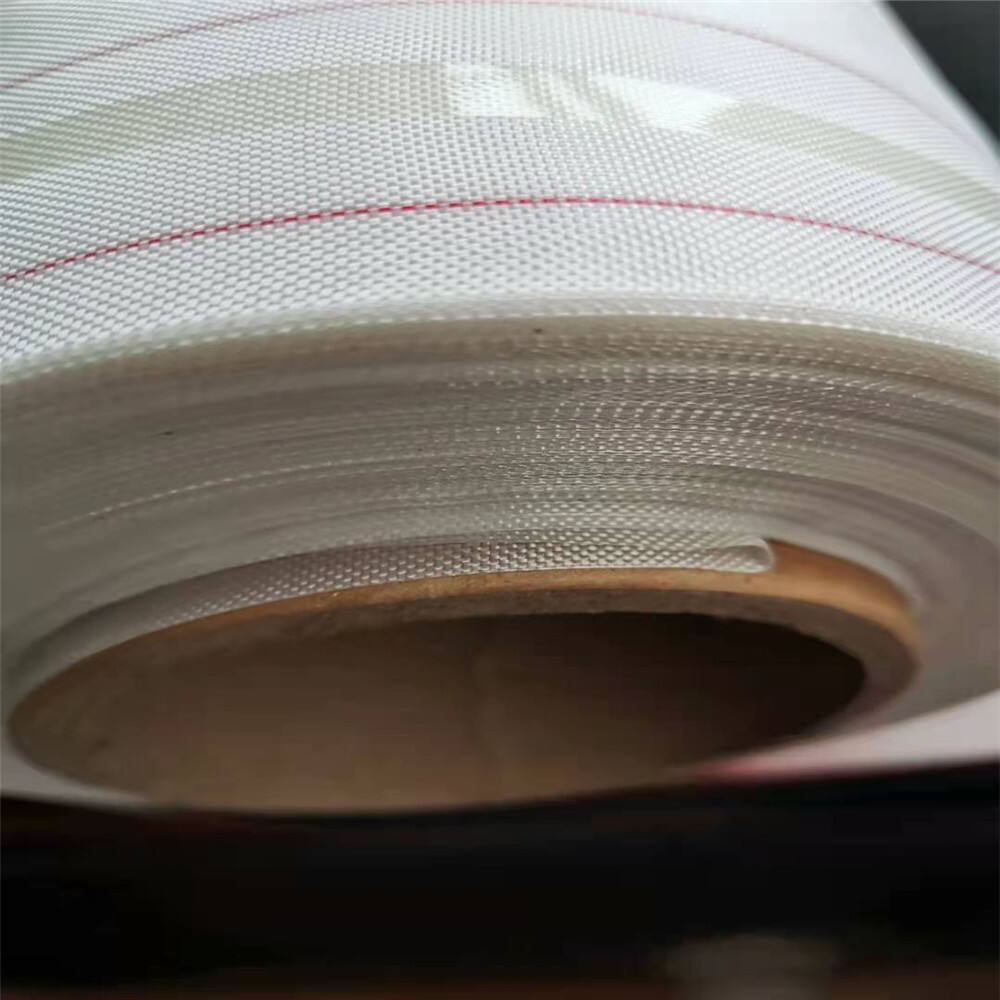

Introducing the AMP Polyester Material Peel Ply for Vacuum Infusion, the clear answer that is ultimate a smooth and also finish for your projects that are composite. This system is designed to be applied into the vacuum infusion procedure for composite fabrication and it is created from high-quality polyester material.

Peel ply is a critical part of the vacuum infusion process, additionally the AMP Polyester Material Peel Ply may be the perfect option for achieving a finish that is perfect. The polyester material is a material that is common when you look at the vacuum infusion process and offers a range of benefits, such as for example moisture resistance, durability, and flexibility.

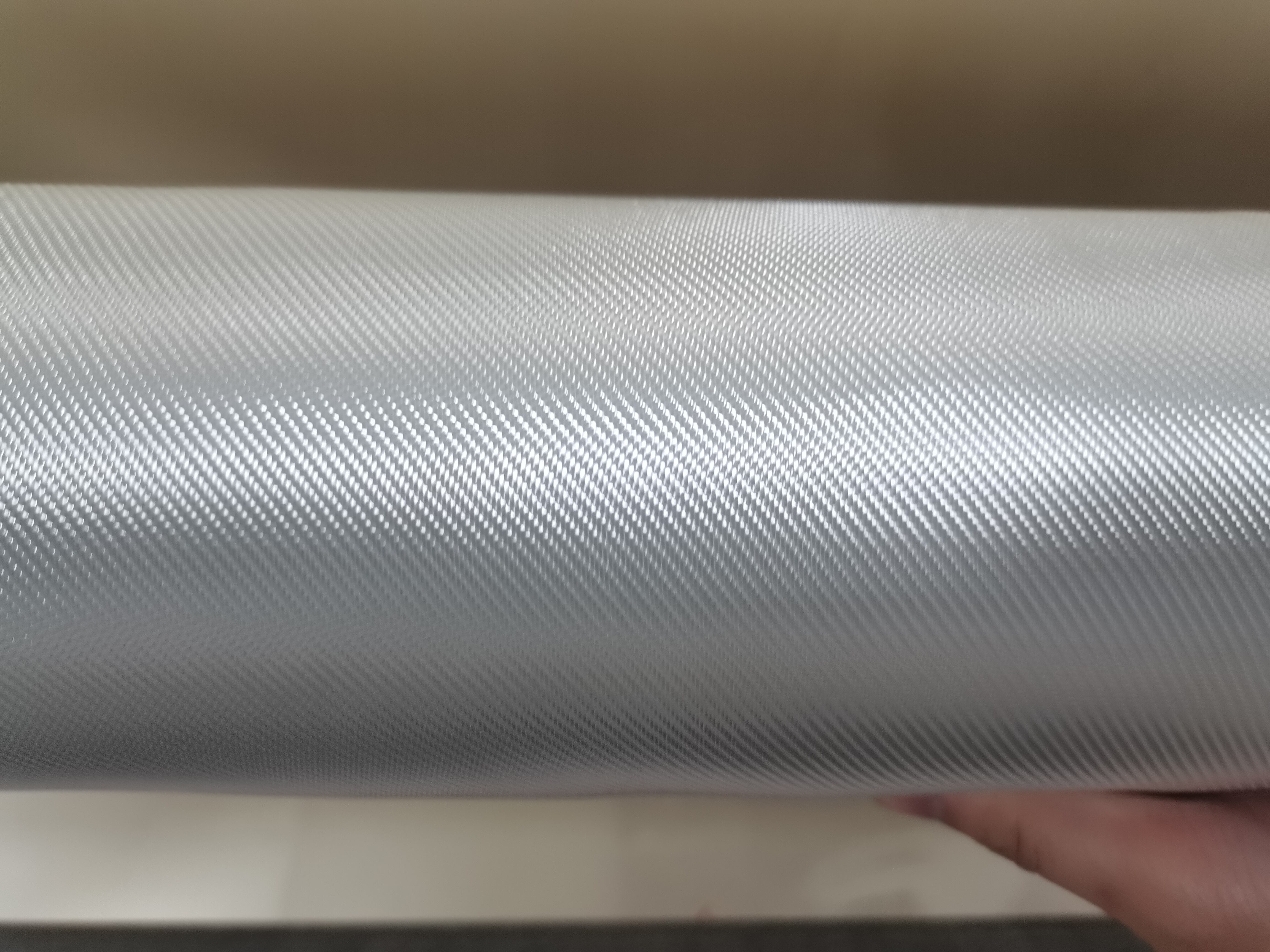

The AMP Polyester Material Peel Ply works by having a wide range of composite materials, including fiberglass, carbon fiber, and Kevlar. It can be employed in both damp and dry lay-up procedures for the wide range of applications, including marine, aerospace, automotive, and architectural tasks.

One of the key top options that come with the AMP Polyester Material Peel Ply is its capacity to promote the release of extra resin during the cleaner infusion process, resulting in a smooth and also finish. The peel ply was created to permit release that is simple of component this is certainly composite the mildew, decreasing the risk of damage and waste.

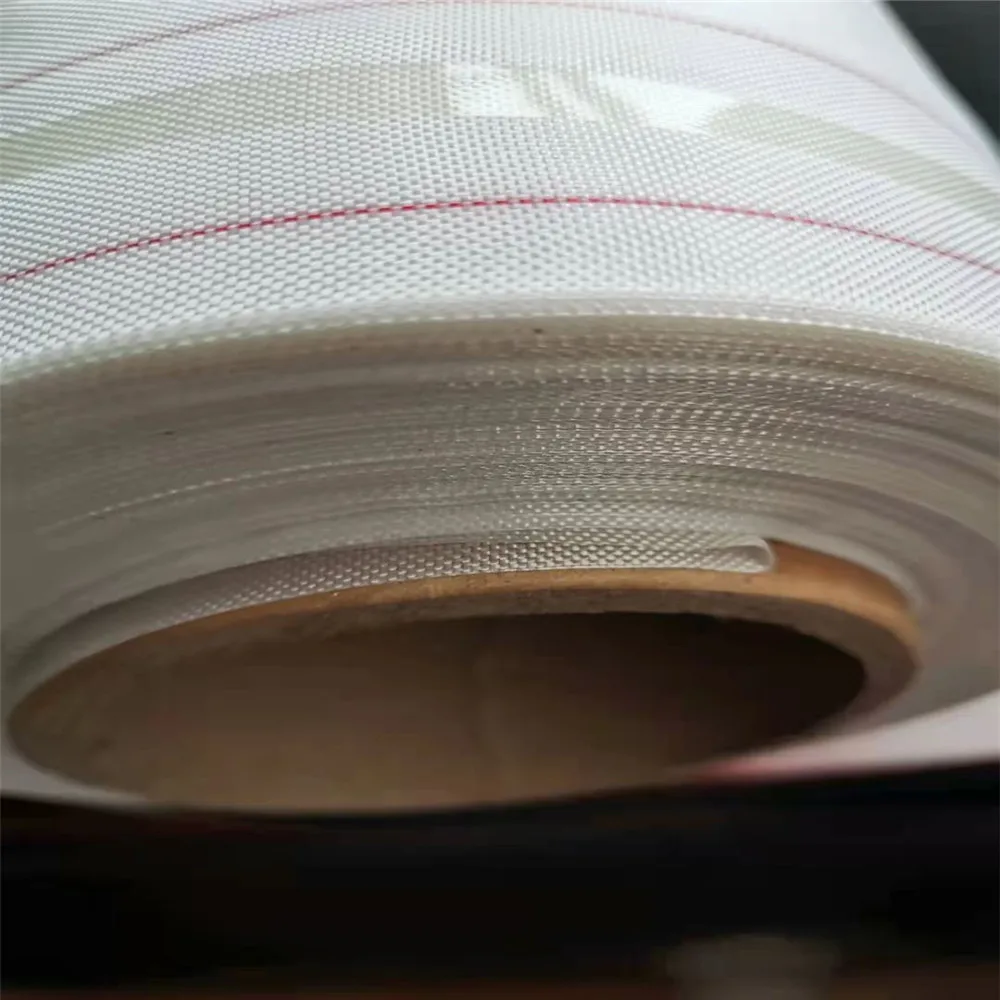

The AMP Polyester Material Peel Ply is lightweight and simple to undertake, rendering it well suited for found in both little and tasks being large. Its available in a variety that is wide of and can be tailored to match the precise requirements of your project.

The AMP Polyester Material Peel Ply can be economical alongside its practical benefits. This is certainly a dependable, top-quality item that delivers outstanding performance, rendering it a fantastic investment for every project that is composite.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ