Benefits of Custom FRP Components for Industry

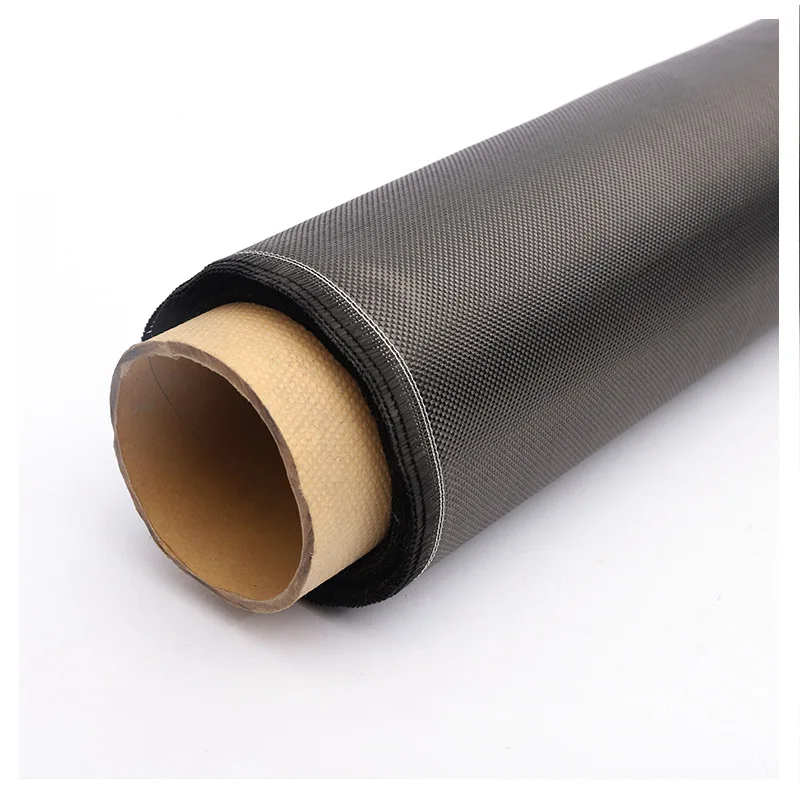

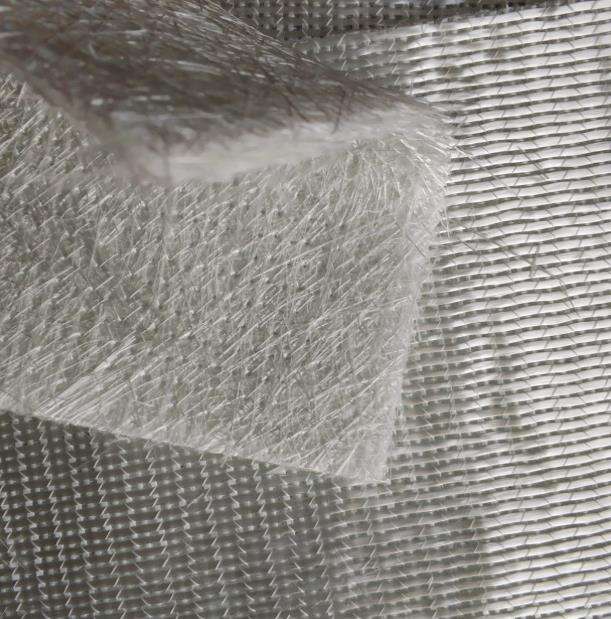

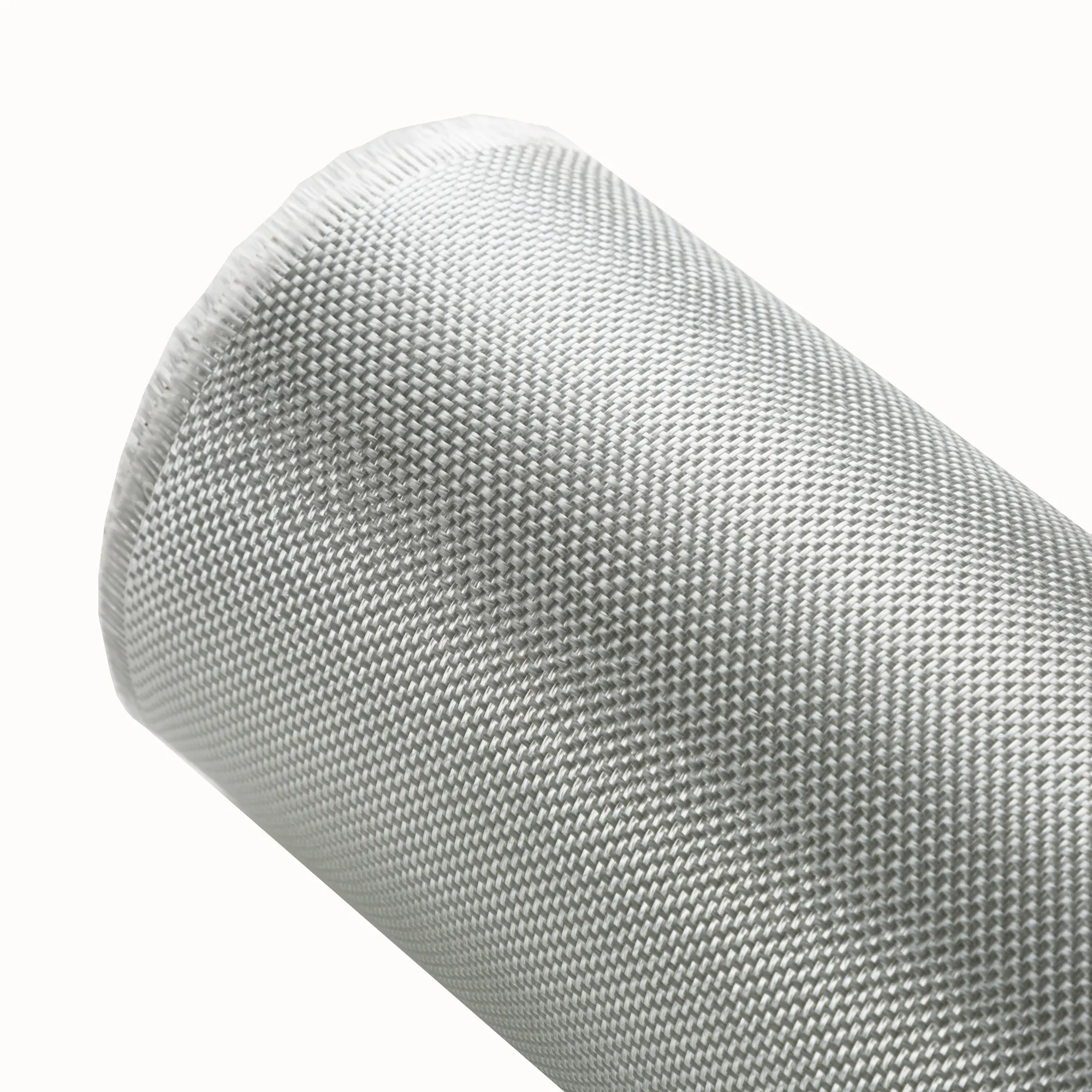

FRP Components are another significant benefit, as these are highly durable. They deal with bad weather, rain and wind, you also don't need to worry about scratches and damage from hits. Ideal for underneath wear and tear spots. Further, FRP does not rust because this material resists corrosion in circumstances like water or chemicals. More so, for products that are used in difficult environments. Finally, perhaps the most important engineering property of FRP is that FRP is non-conductive. It is safe for use in electrical applications whereas electrical or marine applications they will have water.

FRP parts are selected by many companies over traditional materials such as wood, steel and aluminum. Why? But FRP has some cool benefits! It has the ability, for one, to withstand moisture, chemicals and ultraviolet (UV) rays emitted by the sun. Traditional materials such as wood and metal are gradually getting damaged from these elements. This implies that FRP elements have a life span far exceeding that of different substances, allowing agencies to lessen their expenditures over time through avoiding replacements and repairs.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ