- Overview

- Inquiry

- Related Products

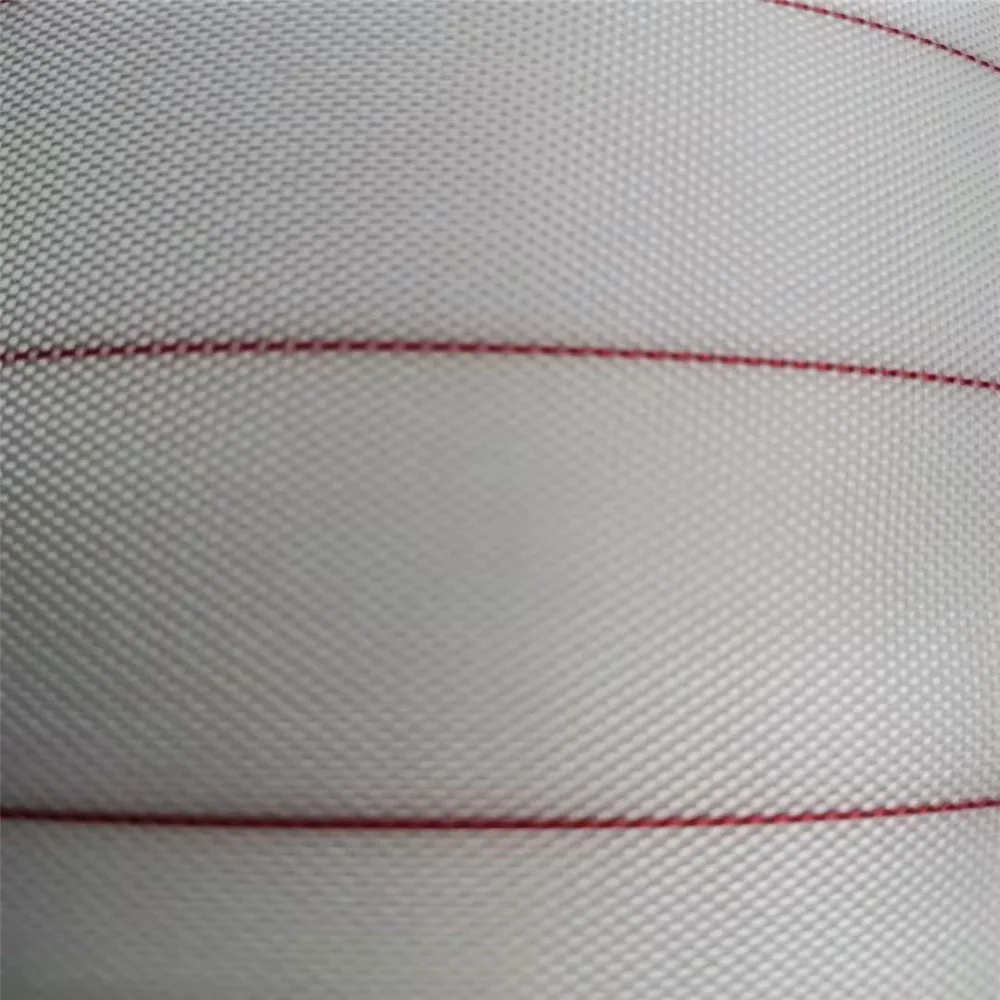

Unlike traditional textiles, it does not require spinning or weaving processes, making it cost-effective and versatile.

Manufacturing Processes:

Common production methods include:

| Type | Process Principle | Characteristics |

|---|---|---|

| Needle-punched Nonwoven | Fibers are mechanically entangled by barbed needles | Thick, durable, breathable |

| Thermal-bonded Nonwoven | Heat rollers melt and bond fibers together | Smooth surface, high strength |

| Spunbond Nonwoven | Polyester granules are melted, spun into filaments, laid into a web, and thermally bonded | Uniform structure, high efficiency |

| Melt-blown Nonwoven | High-speed hot air draws molten polymer into microfibers | Excellent filtration performance |

| Spunlace (Hydroentangled) Nonwoven | High-pressure water jets entangle fibers | Soft texture, lint-free, skin-friendly |

Typical Applications:

| Field | Common Uses |

|---|---|

| Industrial | Filter materials, insulation, automotive interiors, geotextiles |

| Medical & Hygiene | Face masks, gowns, protective clothing, bed covers |

| Home & Daily Use | Upholstery backing, vacuum cleaner bags, wipes, curtains |

| Agriculture | Crop covers, weed control fabric, thermal blankets |

| Packaging | Shopping bags, gift wrapping, protective layers |

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ