- Overview

- Inquiry

- Related Products

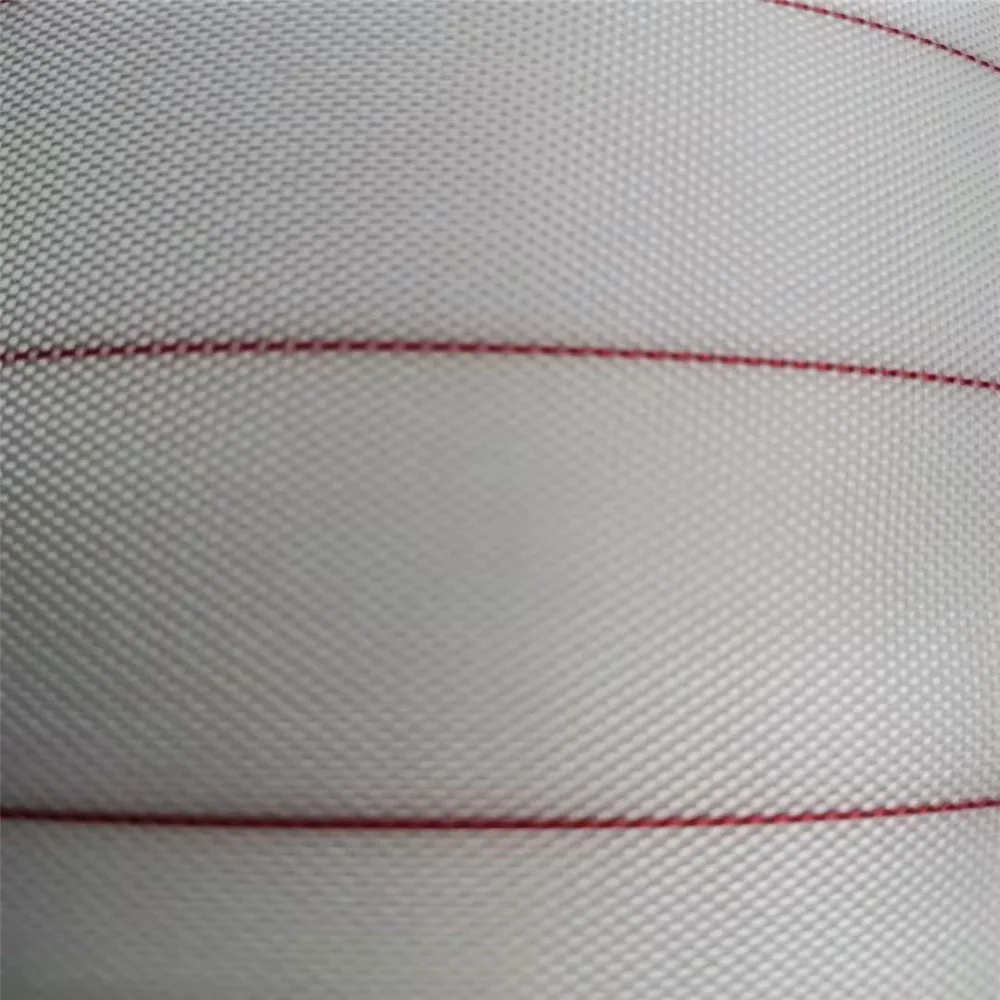

Features of Pultrusion Roving

High Strength:Pultrusion Roving is made from continuous glass fiber bundles, which provide excellent tensile strength, significantly enhancing the structural strength of the composite material, making it suitable for high-load-bearing applications.

Lightweight and High Strength-to-Weight Ratio:Composites made with glass fiber reinforcement offer an excellent strength-to-weight ratio, making them ideal for applications that require high strength with low weight, such as in transportation and construction industries.

Excellent Corrosion Resistance:Glass fibers are highly resistant to corrosion, making Pultrusion Roving ideal for applications in marine environments, chemical industries, and other harsh conditions where metal components would degrade.

Electrical Insulation:Pultrusion Roving provides good electrical insulation properties, making it suitable for use in electrical equipment and electronic components, ensuring safety in high-voltage environments.

High Temperature Resistance:Glass fibers retain their physical properties at elevated temperatures, allowing pultruded composites to withstand high-temperature environments, making them suitable for use in thermal equipment and applications.

Customizable:Pultrusion Roving can be customized in terms of fiber orientation, resin types, and fiber density, allowing manufacturers to achieve specific mechanical properties such as tensile strength, rigidity, and impact resistance based on application needs.

Applications of Pultrusion Roving

Construction and Infrastructure:Pultrusion Roving is used to produce pultruded profiles such as beams, columns, gratings, and structural supports for bridges, buildings, and other infrastructure projects, offering strong and durable structural components.

Transportation:In the transportation sector, Pultrusion Roving is used to manufacture lightweight structural components for automobiles, buses, railcars, and aircraft, helping reduce weight and improve fuel efficiency.

Marine Engineering:Due to its excellent corrosion resistance, Pultrusion Roving is widely used in marine applications, including boat hulls, decks, offshore platforms, and marine pipelines.

Oil and Gas:Pultrusion Roving is used in the oil and gas industry to produce components for offshore platforms, chemical processing equipment, and pipelines, where corrosion resistance and structural integrity are critical.

Electrical and Electronics:Pultrusion Roving is used to manufacture electrical components such as cable trays, support structures, and electrical enclosures, where electrical insulation and high strength are essential.

Sports and Recreation:Pultrusion Roving is also used in the production of sports equipment, such as skis, golf clubs, and sailboats, due to its excellent strength and durability.

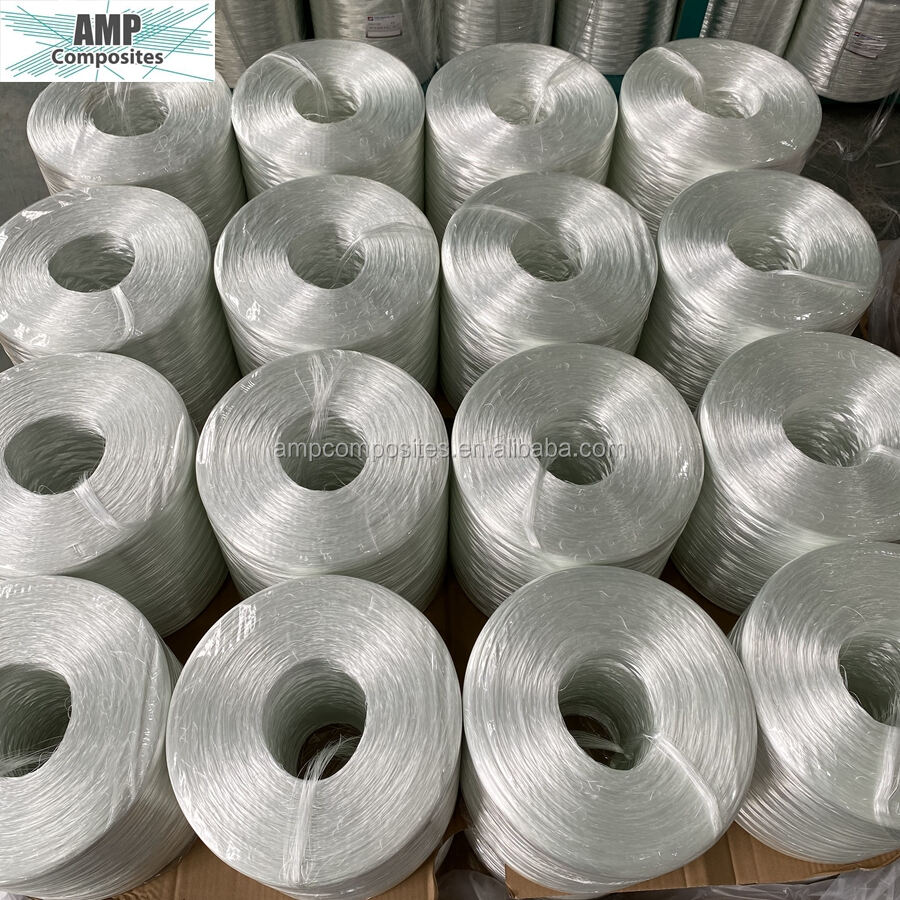

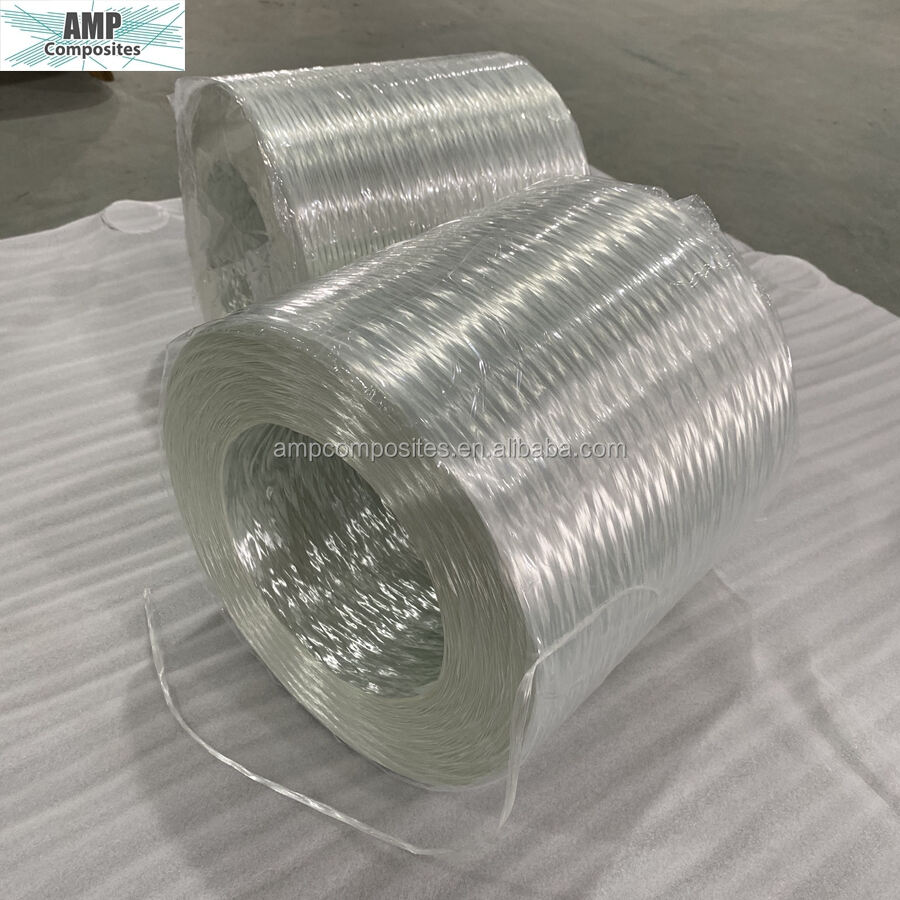

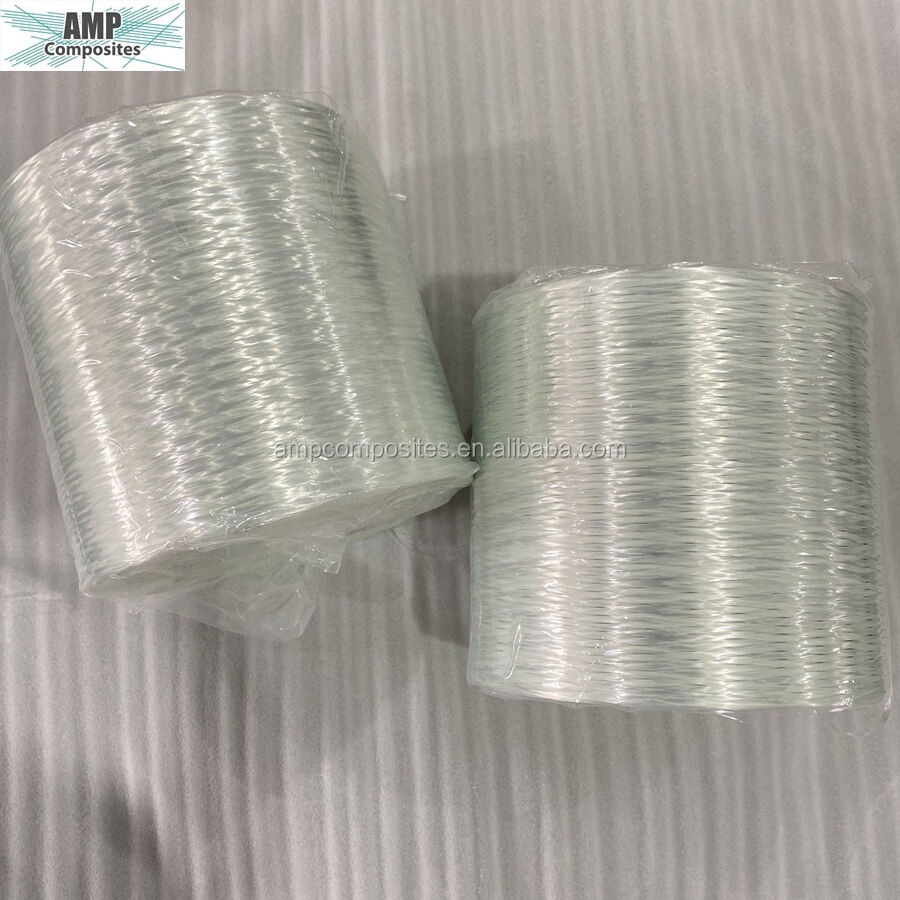

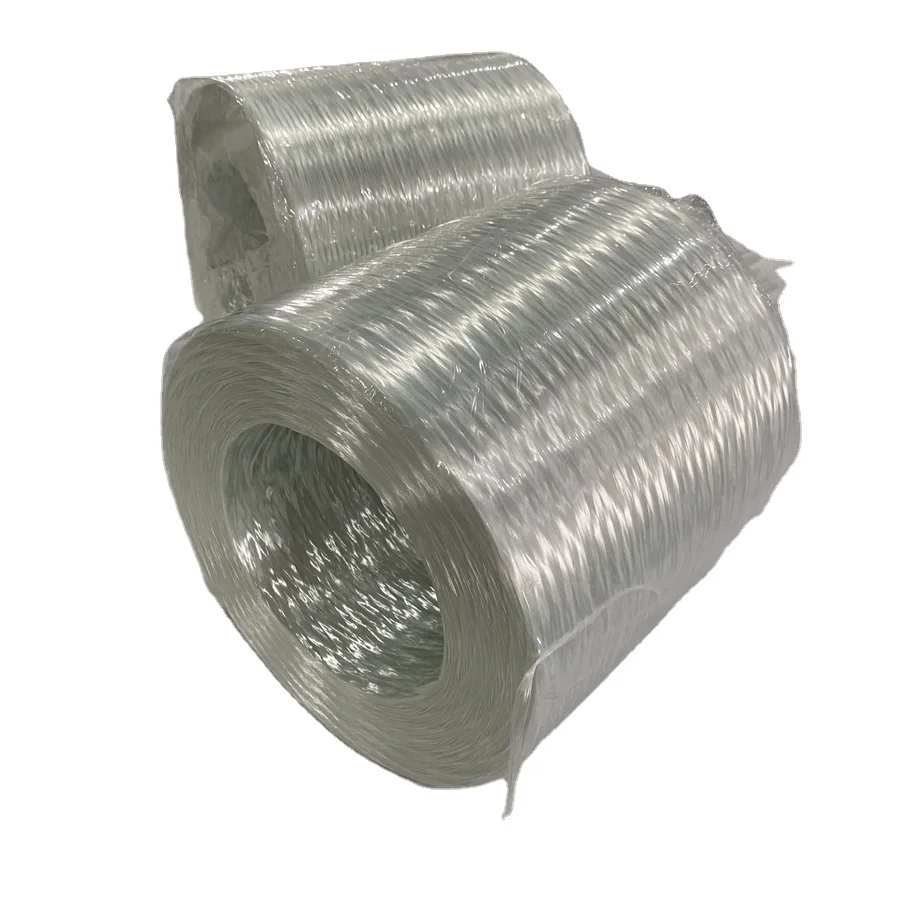

Packaging Specifications of Pultrusion Roving

Rolls:Pultrusion Roving is often packaged in large rolls, which are convenient for continuous pultrusion processes. Each roll typically weighs between 20 to 100 kg, and the weight can be customized according to the customer's requirements.

Spools:For shorter production cycles or specific applications, Pultrusion Roving can also be packaged on spools, typically weighing between 5 to 25 kg per spool.

Special Packaging:In certain environments (e.g., for moisture protection or to prevent damage), Pultrusion Roving may be packaged with protective materials such as waterproof plastic wraps, cardboard boxes, or wooden pallets.

Size and Length:The length of glass fiber strands can be customized based on customer needs, typically ranging from several hundred meters to several thousand meters. The length is adjusted depending on the pultrusion process speed and the final product requirements.

Storage Conditions:Pultrusion Roving should be stored in dry, well-ventilated environments to avoid exposure to high temperatures, moisture, or direct sunlight, ensuring its quality and stability during storage and transport.

Pultrusion Roving is a high-performance reinforcement material used in the pultrusion process, offering excellent strength, corrosion resistance, electrical insulation, and high-temperature resistance. It is widely used in industries such as construction, transportation, marine, oil & gas, and electrical engineering. Pultrusion Roving can be customized to meet specific mechanical, thermal, and electrical performance requirements, and it is available in various packaging formats, including rolls and spools, to meet customer needs. This product helps create strong, lightweight, and durable composite materials for a wide range of applications, providing efficient and cost-effective solutions for modern engineering and manufacturing needs.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

SL

SL

VI

VI

SQ

SQ

TH

TH

AF

AF

MS

MS

HY

HY

KA

KA

JW

JW

LA

LA

NE

NE

PA

PA

MY

MY

KK

KK

TG

TG

UZ

UZ